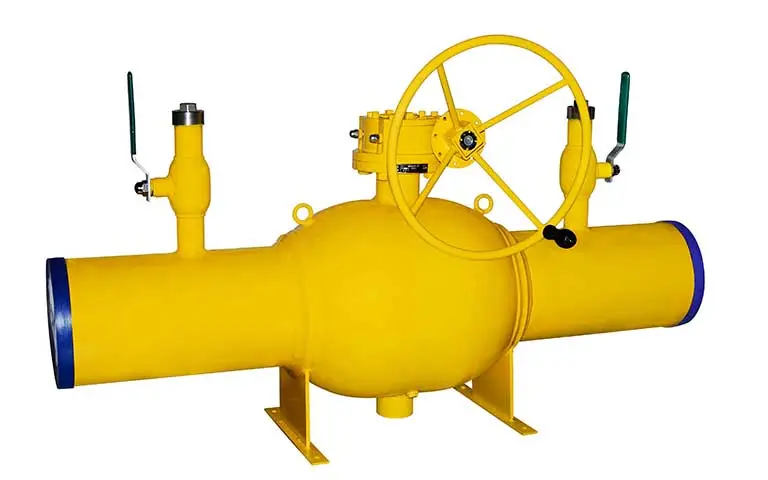

High-Performance Gas Ball Valves for Natural Gas & Oil Applications

Industry Trends and Market Insights for Gas Ball Valves

The global gas ball valves market is growing rapidly, underpinned by rising energy demand, stringent safety standards, and the shifting landscape towards automation and sustainability. According to industry research, the ball valve market is projected to reach USD 16 billion by 2028, with gas sector utilization comprising nearly 40% of installations.

Focusing on **natural gas ball valve** and **oil and gas ball valve** variants, industries emphasize reliability, corrosion resistance, automation compatibility, and compliance with ISO/ANSI standards. Technological advances such as smart actuation, fire-safe designs, and advanced surface coatings are shaping market demands.

Technical Parameters Overview & Product Specifications

Gas ball valves are quarter-turn valves employing a spherical closure unit (the "ball") to regulate gas flow. Key performance characteristics include pressure rating, body material, seat material, end connection types, and durability. The following table compares major industry specifications for reference:

| Parameter | DN 15-800mm Oil and Gas Welded Ball Valve | Leading Brand A | Leading Brand B |

|---|---|---|---|

| Bore Size | DN15 - DN800 | DN20 - DN600 | DN15 - DN600 |

| Pressure Class | PN16/PN25/PN40/PN64, ANSI150/300/600 | PN16-40, ANSI150/300 | PN16-40 |

| Design Standard | API 6D, ISO 14313, ASME B16.34 | ISO 17292, API 608 | API 600, EN12516 |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel | WCB, CF8M, LCB | CF8, WCB |

| End Connection | Welded (BW/SW), Flanged | Threaded, Flanged | Flanged, Socket Weld |

| Seat Material | PTFE, RPTFE, Nylon, Peek, Metal | PTFE, Devlon, POM | PTFE, Nylon |

| Fire Safe | Yes (API 607) | No | Yes |

| Operating Temp. | -46°C to +200°C | -29°C to +180°C | -30°C to +175°C |

| Certification | API, ISO, CE, SIL | ISO, CE | API, CE |

| Estimated Life | >25 years | 10-15 years | 15-18 years |

Manufacturing Process of Gas Ball Valves

Step-by-Step Process (with Key QC Points):

- Material Selection: Verified carbon steel/stainless steel per ASME/ISO standards.

- Casting/Forging: Valve bodies & balls are precision cast or hot-forged; crack checked via ultrasonic NDT.

- CNC Machining: CNC lathes ensure micron-level tolerances on ball roundness and seat finish.

- Surface Treatment: Anti-corrosion coating, fire-safe sealing, cryogenic plating as needed.

- Assembly: Robotic assembly of ball, seat, stem, and housing; torque tested to API 6D.

- Hydrostatic & Pneumatic Testing: 100% pressure, leakage, and sealing integrity test (ISO 5208).

- Final Inspection & Packaging: Barcode traced. Compliance: API, ISO, CE, PED, SIL.

Here is a simplified graphical diagram illustrating the workflow (arrows indicate material/assembly flow):

Technology Advantages of DN 15-800mm Oil And Gas Welded Ball Valve

The gas ball valves from HBYS leverage full-welded design advantages including zero maintenance, high-pressure performance, and anti-blowout features. Notable benefits include:

- 100% Leak-free: Welded body ensures no potential body leakage, especially vital for city gas pipelines.

- Fire-safe, Anti-corrosion: Certified to API 607/ ISO 10497 fire-safe standards and superior coating against hydrogen sulfide and chlorides.

- Long Service Life: Design life exceeding 25+ years, confirmed by accelerated aging test data.

- Automation Ready: Compatible with pneumatic/electric actuators for real-time SCADA integration.

- Wide Bore Options: DN15 to DN800, suitable for municipal, petrochemical, and LNG sectors.

Industry Certifications & Company Credentials

(Pipeline, Fire-safe, Ball Valves)

(Quality Management)

(Pressure Equipment Directive)

(Functional Safety)

HBYS, established in 1988, partners with Sinopec, PetroChina, and international EPCs. Over 30 years of engineering, combined with certifications above, ensures authoritative quality and product traceability.

Request Technical Data SheetGas Ball Valves Application Scenarios & Case Study

Case: Natural Gas Distribution in Urban Main Pipeline (DN600)

HBYS supplied 50 sets of DN600 full welded **gas ball valves** to the Hangzhou City Gas Expansion Project. The valves underwent 100% hydrostatic and low-temperature (−46°C) testing. Field data over 7 years shows:- Zero internal leakage detected

- No corrosion on body/trim despite H₂S content (verified by ultrasonic thickness test)

- Automated SCADA remote opening/feedback with 98.9% uptime

- Energy savings: Pipeline loss reduction by 3.1% (vs. previous cast/fixed ball valve design)

Oil and gas ball valve products are essential for midstream/downstream logistics, oil tank farms, compressor stations, and LNG regasification units. Their robust mechanical integrity and high cycle life make them preferred for hazardous environments.

Technical Data Visualization & Product Comparison

| Product Parameter | DN 15-800mm Oil and Gas Welded Ball Valve | |

|---|---|---|

| Main Specs | Size Range | DN15-DN800 (1/2"~32") |

| Pressure | PN16/25/40/64; ANSI 150/300/600 | |

| Design | Full Welded, Trunnion Mounted | |

| Body Material | Carbon Steel (A105), Stainless (304/316), Alloy | |

| Seat Material | PTFE, RPTFE, Metal, PEEK, Devlon | |

Customized Solutions & Delivery/Support

- Engineering Design: Adaptable for buried/aboveground, high/low temperature, and acid gases.

- Optional coatings: FBE (Fusion-Bonded Epoxy), PTFE lining, anti-static springs

- Quick Delivery: 4-8 weeks for most standard sizes; expedite service for shutdowns.

- Warranty: 36 months from shipment or 30,000 cycles (whichever occurs first).

- Technical Support: 24/7 hotline and remote troubleshooting; on-site start-up/training worldwide.

Every gas ball valves order is provided with traceable test and inspection records, operator manuals, and spare kits.

FAQs & Expert Answers for Oil and Gas Ball Valve Selection

A: For H₂S-rich or sour gas, NACE MR0175/ISO 15156-approved stainless or alloy steels are mandatory, with anti-sulfide embrittlement treatment and PTFE/Peek seats.

A: Pressure class is defined by process max pressure/temp per ASME/EN charts. Typical PN16/PN40 or ANSI 150/300/600 are used based on network pressure and code compliance.

A: PTFE is standard for inert/non-abrasive gas. For high-cycle/abrasive duties, RPTFE, Devlon, or metal seats with chrome-plated balls excel in wear, extending service life.

A: Major standards: API 598/ISO 5208 (leakage/pressure), API 6D (pipeline valves), API 607 (fire-safe), EN 12266, CE/PED marking.

A: Align the piping axially, use correct torque on bolts, verify gasket compatibility (graphite/PTFE), and perform pre-commissioning hydrotests. Always reference API 6D install guidelines.

A: Yes. HBYS offers >=3m stem extensions, gearboxes, and integrates with most pneumatic/electric actuators including remote monitoring/diagnostics.

A: Standard: 3 years warranty, 24/7 tech support, rapid spare dispatch, and lifecycle valve health audits onsite or remotely.

Conclusion & Industry References

In summary, gas ball valves—especially the DN 15-800mm Oil and Gas Welded Ball Valve—offer robust performance, long life, and compliance to global standards for the most demanding oil & gas and industrial environments. Trust is further anchored by market references and authoritative certification.

• [Valve Magazine — Technology Spotlight: Ball Valves](https://www.valvemagazine.com/industry-headlines/industry-insights/itemlist/tag/Ball%20Valve)

• [Valve World Journal: Best Practices for Oil & Gas Pipeline Valves](https://www.valve-world.net/magazine/)

• [API/ISO Testing Standards – API 6D, API 607, ISO 5208](https://www.api.org/products-and-services/standards)

• [Control Global: Ball Valve Selection for Gas Service](https://www.controlglobal.com/)

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025