Reliable Rubber Joints for Pipe Expansion & Vibration

Understanding the Critical Role of Rubber Joints in Industrial Systems

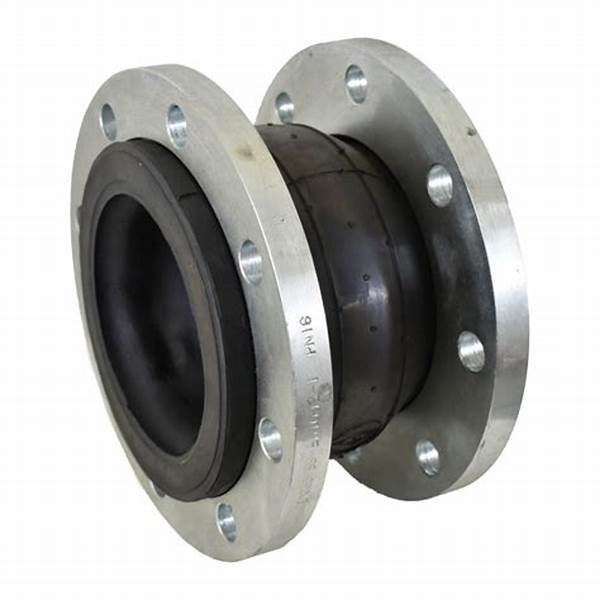

In complex industrial piping systems, the ability to absorb movement, stress, and vibration is paramount for operational integrity and longevity. This is where rubber joints, particularly specialized components like the JGD41-10/16 Rubber Curved Joints, play a pivotal role. These flexible connectors are engineered to compensate for thermal expansion or contraction, isolate vibration from pumps and other equipment, and protect sensitive piping from transient pressure surges. Their versatile design makes them indispensable across a multitude of sectors, ensuring system reliability and reducing maintenance overhead. The continued evolution of material science and manufacturing techniques further enhances their performance envelopes, allowing for applications in increasingly demanding environments.

The demand for robust and adaptable rubber expansion joint solutions continues to grow, driven by the expansion of industrial infrastructure and the need for greater efficiency and safety. Modern industrial facilities, from power plants to chemical processing units, rely on these components to maintain system integrity under fluctuating operational conditions. Investing in high-quality rubber joints ensures a resilient piping network that can withstand the rigors of continuous operation, thereby minimizing downtime and extending the service life of critical assets. Our focus here is to delve into the technical nuances, application versatility, and the underlying quality assurance that defines superior flexible connector solutions.

Technical Parameters and Performance Benchmarks for Rubber Expansion Joints

Selecting the appropriate rubber joints requires a thorough understanding of their technical specifications and how these parameters influence performance in specific operating environments. Key technical parameters include nominal diameter (DN), working pressure, temperature range, and maximum movement capabilities (axial compression, extension, lateral deflection, angular deflection). The material composition of the rubber body, often a blend of natural rubber, EPDM, NBR, or Neoprene, along with reinforcement layers of synthetic fabric and metal rings, dictates its chemical resistance, temperature tolerance, and pressure handling capacity.

Pressure ratings, typically denoted as PN (Nominal Pressure) or Class, are crucial for ensuring the joint can safely withstand the system's internal pressure. Temperature limits define the operational range without material degradation, while movement capabilities specify the joint's flexibility in accommodating pipeline shifts. Understanding these parameters is essential for engineers designing robust piping systems, ensuring the longevity and safety of the installation. For instance, a general rubber expansion joint designed for a water treatment plant will have different specifications compared to one used in a high-temperature petrochemical application.

Comparative Table of Typical Rubber Joint Parameters

| Parameter | Description | Typical Range (Standard Duty) | Considerations for Severe Duty |

|---|---|---|---|

| Nominal Diameter (DN) | Internal pipe diameter matched | DN25 - DN3000 (1" - 120") | Custom sizes for large pipelines |

| Working Pressure | Maximum continuous operating pressure | PN10 / 1.0 MPa (150 psi) | PN16, PN25+ (Higher ratings require specific reinforcement) |

| Temperature Range | Safe operating temperature limits | -15°C to +80°C (EPDM) | -40°C to +150°C (Specific compounds like Hypalon/Viton) |

| Axial Compression | Shortening along the axis | 5mm - 30mm (0.2" - 1.2") | Larger movements for seismic zones, specialized designs |

| Lateral Deflection | Offset parallel to joint face | 5mm - 25mm (0.2" - 1.0") | Required for misalignment, settlement issues |

| Angular Deflection | Rotational movement | 4° - 15° | Crucial for pipe settlement or shifting foundations |

The Advanced Manufacturing Process of High-Performance Rubber Joints

The production of a robust rubber expansion joint is a sophisticated process that combines material science with precision engineering. It typically begins with the careful compounding of raw rubber (e.g., natural rubber, EPDM, NBR) with various additives, accelerators, and fillers to achieve specific mechanical and chemical properties. This meticulously prepared compound then undergoes calendering or extrusion to form sheets, which are subsequently cut and shaped for the joint's body. Fabric reinforcement layers, usually made from high-strength nylon or polyester, are then integrated to provide the necessary structural integrity and pressure resistance.

The core of the manufacturing process for a general rubber expansion joint involves molding and vulcanization. The assembled raw joint structure is placed into a specialized mold, which is then subjected to high pressure and temperature. This vulcanization process chemically cross-links the polymer chains, transforming the soft, pliable rubber compound into a durable, elastic, and stable material capable of withstanding extreme conditions. This stage is critical for achieving the joint's final shape, resilience, and resistance to environmental factors. Post-vulcanization, the joints undergo trimming, flange attachment (if applicable), and rigorous quality inspections.

Quality control is integrated at every stage, from raw material inspection to final product testing. This includes material property tests, hydrostatic pressure tests, vacuum tests, and dimensional checks, all conforming to international standards such as ISO 9001 and specific industry benchmarks like ANSI/AWWA C207 for flanges or the Fluid Sealing Association (FSA) standards for rubber joints. This meticulous process ensures that each product, including the specialized JGD41-10/16 Rubber Curved Joints, delivers optimal performance, an extended service life of typically 5-10 years or more depending on application, and superior resistance to corrosion and abrasion, contributing significantly to energy efficiency by reducing pipeline stress.

Diverse Applications Across Key Industries

The versatility of rubber joints makes them indispensable in a wide array of industrial applications. In the petrochemical industry, they manage thermal expansion in critical pipelines carrying hydrocarbons, preventing stress-induced failures. Within metallurgy, particularly in steel mills, these joints absorb vibrations from heavy machinery and accommodate movement in high-temperature water cooling lines. Their anti-corrosion properties are highly valued in chemical processing plants, where they safely handle aggressive media, protecting metal piping from deterioration.

For water supply and drainage systems, a rubber expansion joint for pipe applications is crucial for absorbing ground settlement, seismic activity, and surges in pressure, thus protecting municipal infrastructure. Power generation plants use them extensively in cooling water intake and discharge lines, condenser connections, and scrubber systems to handle large volumes of water and mitigate vibration from turbines and pumps. Moreover, in HVAC systems for large commercial buildings, they isolate vibration from chillers and pumps, significantly reducing noise transmission and extending the lifespan of mechanical equipment. The specialized JGD41-10/16 Rubber Curved Joints are particularly effective in tight spaces or where specific directional movement compensation is required, showcasing their adaptability.

Strategic Advantages of Superior Rubber Joints and Customization Options

Opting for high-quality rubber joints brings a myriad of strategic advantages to any industrial operation. Beyond their primary function of accommodating movement, they significantly reduce noise and vibration transmission, creating a more stable and quieter working environment. Their inherent elasticity and dampening properties protect adjacent equipment, such as pumps and valves, from undue stress, thereby extending their operational lifespan and reducing maintenance costs. Furthermore, their non-conductive nature can provide electrical isolation in certain applications, adding another layer of safety.

Manufacturers often provide extensive customization options for rubber expansion joint for pipe systems to meet unique project requirements. This includes variations in material compounds for specific chemical resistance or temperature ranges, multi-arch designs for greater movement absorption, or specialized flange materials and drilling patterns to match existing piping. For instance, in an application handling abrasive slurries, a natural rubber compound might be preferred for its superior abrasion resistance, while in a high-temperature steam line, an EPDM or Viton liner would be more suitable. This bespoke approach ensures optimal fit and performance, avoiding compromises that could lead to premature failure or operational inefficiencies.

Ensuring Trust and Authority: Certifications and Real-World Impact

The credibility of a rubber joints manufacturer is built upon a foundation of rigorous quality assurance and adherence to international standards. Certifications such as ISO 9001 for quality management systems are non-negotiable, demonstrating a commitment to consistent product quality. Beyond this, compliance with industry-specific standards like ANSI (American National Standards Institute), DIN (Deutsches Institut für Normung), or JIS (Japanese Industrial Standards) for flange dimensions and pressure ratings ensures interoperability and safety across global markets. Many reputable manufacturers also possess certifications for specific applications, such as FDA compliance for food-grade general rubber expansion joints or ATEX directives for potentially explosive atmospheres.

Our company's long-standing service record, spanning over two decades, is testament to our unwavering commitment to producing reliable and high-performance industrial valves and rubber connectors. We regularly conduct internal testing, including burst pressure tests, cyclic fatigue tests, and material aging tests, providing verifiable data to our clients. Our collaborative partnerships with engineering firms and contractors globally further underscore our authoritative position in the industry, contributing to successful projects from large-scale municipal waterworks to specialized industrial process lines. These tangible examples of expertise and trusted partnerships reinforce our dedication to delivering solutions that meet and exceed stringent industry requirements, giving our clients confidence in every installation.

Frequently Asked Questions (FAQ) about Rubber Expansion Joints

Q1: What is the typical lifespan of a rubber expansion joint?

A1: The lifespan of a rubber expansion joint varies significantly based on operating conditions (temperature, pressure, media), frequency and magnitude of movement, and proper installation. Generally, they are designed for a service life of 5 to 10 years, but under ideal conditions and with proper maintenance, they can last longer. Regular inspections are recommended to monitor their condition.

Q2: Can rubber joints be used for highly corrosive chemicals?

A2: Yes, specific rubber compounds are formulated to resist a wide range of corrosive chemicals. For example, Hypalon is excellent for strong acids and oxidizers, while Viton is ideal for hydrocarbons and high temperatures. It's crucial to select the correct rubber material based on the chemical compatibility chart for the media being conveyed.

Q3: How do rubber expansion joints compare to metal bellows?

A3: Rubber joints offer superior vibration and noise absorption, greater flexibility in absorbing multiple movements simultaneously (axial, lateral, angular), and are generally more cost-effective for lower pressures and temperatures. Metal bellows are preferred for very high temperatures, pressures, and where minimal movement is required, but they offer less vibration dampening.

Q4: What information is needed for a custom rubber joint solution?

A4: For a customized rubber expansion joint for pipe, key information includes nominal pipe size (DN), operating pressure and temperature, type of media (and its chemical composition), maximum expected movements (axial, lateral, angular), flange drilling standard, and any specific environmental or installation constraints. Our technical team can assist in gathering these details.

Commitment to Service: Delivery, Warranty, and Support

Understanding the critical nature of timely project completion, we emphasize efficient delivery cycles for all our products, including specialized rubber joints. Standard products typically have shorter lead times, while custom solutions may require additional time for engineering and manufacturing, always communicated transparently upfront. Our logistics team works diligently to ensure on-time delivery, minimizing any potential project delays for our clients. We offer various shipping options to accommodate diverse client needs and geographic locations, leveraging our extensive supply chain network.

Every JGD41-10/16 Rubber Curved Joints and other general rubber expansion joints we produce is backed by a comprehensive warranty, affirming our confidence in the quality and durability of our products. This warranty covers manufacturing defects and material failures under normal operating conditions, providing peace of mind to our customers. Our dedicated customer support team is available to assist with product selection, technical inquiries, installation guidance, and any post-sales support required. We believe in building lasting relationships through reliable products and responsive service, ensuring that our clients receive continuous value throughout the product lifecycle.

Conclusion: Engineered Resilience for Modern Industrial Demands

In an era of increasingly complex and demanding industrial processes, the integrity and flexibility of piping systems are more critical than ever. Rubber joints stand as essential components, providing engineered solutions for managing stress, vibration, and movement, thereby safeguarding critical infrastructure and optimizing operational efficiency. From their meticulous manufacturing process involving specialized rubber compounds and rigorous quality checks to their diverse applications across petrochemical, metallurgy, and water treatment sectors, these components are vital.

By offering a blend of technical superiority, customization capabilities, and unwavering commitment to quality and support, advanced rubber expansion joint solutions ensure that industrial systems operate with enhanced safety, longevity, and cost-effectiveness. The continuous innovation in material science and design methodologies further solidifies their role as indispensable assets in modern industrial engineering.

References

- Fluid Sealing Association. (2007). FSA Technical Handbook: Non-Metallic Expansion Joints.

- ASME B31.3. (2020). Process Piping. American Society of Mechanical Engineers.

- ISO 9001:2015. (2015). Quality management systems — Requirements. International Organization for Standardization.

- AWWA Manual M11. (2004). Steel Pipe - A Guide for Design and Installation. American Water Works Association.

- Goodyear Engineered Products. (2010). Handbook of Industrial Hoses & Expansion Joints.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025