Reliable Rubber Joints: General Expansion Joints for Pipes

Navigating the Evolving Landscape of Industrial Fluid Management with Rubber Joints

The industrial landscape is continuously evolving, demanding increasingly sophisticated solutions for fluid handling systems. Central to this evolution are advanced rubber joints, critical components designed to accommodate movements, alleviate stress, reduce noise, and isolate vibration in piping systems. As global industries push boundaries in efficiency, sustainability, and operational longevity, the demand for high-performance rubber expansion joints that can withstand extreme conditions and offer unparalleled reliability is surging. This heightened requirement is driven by the expansion of sectors such as petrochemicals, power generation, water treatment, and HVAC, all of which rely heavily on robust and adaptable pipeline infrastructure. The adoption of new materials, innovative manufacturing techniques, and stringent quality control measures are transforming the capabilities of general rubber expansion joints, moving them beyond simple flexible connectors to sophisticated engineered solutions. This trend emphasizes bespoke designs, improved material compatibility for diverse media, and enhanced durability against aggressive chemical environments and fluctuating temperatures, ensuring that systems operate smoothly and safely with minimal downtime and maintenance.

Industry statistics reinforce this growth, with the global industrial expansion joint market projected to reach significant valuations by the mid-2020s, driven primarily by infrastructure development and the modernization of existing facilities. End-users are increasingly prioritizing solutions that offer not only immediate cost-effectiveness but also long-term value through reduced operational expenditures and extended service life. The technical parameters of modern rubber expansion joint for pipe applications are becoming more critical than ever, influencing system design and performance. Engineers and procurement specialists are meticulously evaluating factors such as pressure ratings, temperature resistance, material composition, and deflection capabilities to ensure optimal system integrity and compliance with international standards. Furthermore, the focus has shifted towards sustainable manufacturing practices and the development of eco-friendly elastomeric compounds that meet stringent environmental regulations while maintaining superior performance. This comprehensive approach to product development ensures that the next generation of rubber joints not only meets current industrial demands but also anticipates future challenges, contributing significantly to more resilient and efficient global infrastructure.

Technical Specifications and Performance of Rubber Expansion Joints

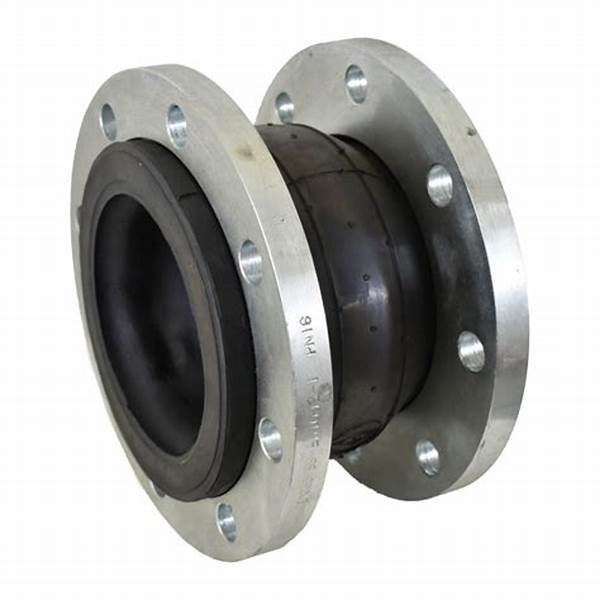

Understanding the technical parameters of rubber joints is paramount for selecting the right component for any demanding industrial application. These critical specifications dictate a joint's ability to perform under specific operational conditions, ensuring both safety and longevity within a piping system. Key parameters include the nominal diameter (DN), which defines the pipe size the joint is designed for, and the rated working pressure, typically measured in MPa or PSI, indicating the maximum internal pressure the joint can safely withstand. Temperature range is another vital specification, often encompassing a broad spectrum from sub-zero to high-temperature steam applications, requiring specialized elastomeric compounds like EPDM, NBR, or Neoprene to maintain flexibility and integrity. Axial compression, axial extension, lateral deflection, and angular deflection are crucial movement capabilities, defining how much displacement the joint can absorb in various directions without compromising its structural integrity. Furthermore, the vacuum rating specifies the joint's ability to operate under negative pressure conditions without collapsing. The specific product, JGD41-10/16 Rubber Curved Joints, exemplifies a specialized design for accommodating angular and lateral movements in complex piping layouts, making it highly effective in scenarios where traditional straight expansion joints might struggle due to spatial constraints or system geometry.

The performance of rubber joints is intrinsically linked to their material composition and structural design. High-quality general rubber expansion joints feature multiple layers of synthetic fabric reinforcement, often nylon or polyester, embedded within the rubber body to enhance strength and prevent ballooning under pressure. The outer cover protects against external abrasion, weathering, and chemical splash, while the inner liner is selected based on compatibility with the conveyed media, preventing corrosion or degradation from aggressive fluids. Flange materials, typically carbon steel, stainless steel, or ductile iron, are critical for secure connections to piping systems and are often coated or plated for corrosion resistance. For instance, the JGD41-10/16 Rubber Curved Joints, specifically designed for pipe applications, integrates these material sciences to deliver superior performance. These joints are engineered to withstand not only mechanical stresses but also environmental factors, ensuring a prolonged service life. Their design minimizes reactive forces on adjacent equipment, thereby extending the lifespan of the entire system and reducing the need for costly maintenance. The selection process mandates a thorough understanding of these specifications to match the joint's capabilities with the operational demands, thereby ensuring optimal system performance and long-term reliability.

Typical Rubber Joint Parameter Table

| Parameter | Standard Range | Specifics for JGD41-10/16 (Example) |

|---|---|---|

| Nominal Diameter (DN) | DN32 - DN3000 | DN100 - DN800 (Common) |

| Working Pressure (MPa) | 0.25 - 2.5 MPa | 1.0 MPa (Standard for JGD41) |

| Temperature Range (°C) | -15°C to +120°C (depending on material) | -15°C to +100°C (EPDM Liner) |

| Axial Compression (mm) | 10 - 50 mm | Approx. 20-30 mm (varies by size) |

| Lateral Deflection (mm) | 10 - 50 mm | Approx. 20-30 mm (varies by size) |

| Vacuum Rating (KPa) | -60 KPa to -80 KPa | -65 KPa (Standard) |

| Flange Material | Carbon Steel, Stainless Steel | Q235 Carbon Steel (Standard) |

The Advanced Manufacturing Process of High-Performance Rubber Expansion Joints

The production of high-quality rubber expansion joints, such as the JGD41-10/16 Rubber Curved Joints, is a meticulous multi-stage process that combines sophisticated material science with precision engineering, deviating significantly from conventional metal component manufacturing like casting or forging. It begins with the careful selection and compounding of elastomeric raw materials, including natural rubber, EPDM, NBR, Neoprene, or Viton, chosen based on their specific chemical resistance, temperature resilience, and flexibility requirements for the intended application. This raw rubber is then mixed with various additives, such as vulcanizing agents (e.g., sulfur), accelerators, activators, fillers (e.g., carbon black), and anti-oxidants, through a precise internal mixing process to achieve the desired physical properties and durability. Following compounding, the rubber is often calendared into thin sheets or extruded into tubes, forming the foundational layers of the joint. Fabric reinforcement layers, typically made from high-strength synthetic fibers like nylon or polyester, are then carefully cut and laid up to provide burst strength and dimensional stability. This multi-ply construction is crucial for enduring high internal pressures and mechanical stresses.

The subsequent stages involve meticulous assembly and vulcanization. The prepared rubber and fabric layers are built up by hand or machine onto a collapsible mandrel, shaping the bellows and integral flange ends. During this build-up, steel reinforcing rings are often incorporated into the neck of the bellows to provide additional stability and prevent flange distortion. Once assembled, the green (uncured) rubber expansion joint for pipe is transferred to a curing press, where it undergoes the vulcanization process. This involves applying controlled heat and pressure, typically in a heated mold, which chemically cross-links the rubber molecules, transforming the pliable raw material into a durable, elastic, and resilient finished product. The duration and temperature of vulcanization are critical parameters, precisely controlled to achieve optimal material properties. After curing, the joint is removed from the mold, deflashed, and subjected to a battery of rigorous quality control tests. These tests include visual inspection for surface defects, dimensional checks against specifications, hydrostatic pressure testing to verify burst strength and leak integrity, vacuum testing, and sometimes even cycle life testing to simulate long-term operational conditions. Compliance with international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material properties, and ANSI/AWWA (American Water Works Association) for specific application requirements ensures that each general rubber expansion joint meets the highest performance and reliability benchmarks, guaranteeing a long service life of 10-15 years under normal operating conditions.

Diverse Applications and Core Advantages of Rubber Joints in Industrial Systems

Rubber joints are indispensable components across a vast spectrum of industrial sectors, owing to their unique ability to absorb movement, isolate vibration, and reduce noise within piping systems. Their versatility makes them critical in environments where thermal expansion, mechanical stress, and equipment vibration are prevalent. In the petrochemical industry, for instance, they are vital for managing thermal expansion in pipelines transporting various hydrocarbons, ensuring system integrity and preventing costly leaks or ruptures. Similarly, in power generation, especially in thermal and nuclear power plants, rubber expansion joints are crucial for accommodating movements in cooling water lines, steam systems, and scrubber systems, contributing to operational efficiency and safety. The metallurgy sector utilizes them to handle abrasive slurries and high-temperature media, where their inherent flexibility and material resilience prevent pipe fatigue and corrosion. In water supply and drainage systems, general rubber expansion joints mitigate pipe stresses caused by ground settlement, seismic activity, or pump vibrations, ensuring reliable water distribution and wastewater management. For the JGD41-10/16 Rubber Curved Joints, their specific design makes them ideal for complex pipe geometries, enabling smooth fluid flow around bends while maintaining system flexibility and absorbing multifaceted movements that straight joints cannot address effectively.

The technical advantages of employing rubber expansion joint for pipe systems are significant, leading to substantial operational benefits. Foremost among these is their superior vibration isolation capability, which protects sensitive equipment like pumps, compressors, and turbines from harmful vibrations transmitted through piping, thereby extending equipment lifespan and reducing maintenance costs. Their elastomeric construction also provides excellent sound attenuation, significantly reducing noise levels in industrial facilities, contributing to a safer and more compliant working environment. From an energy perspective, by effectively absorbing movements and stresses, rubber joints minimize friction and turbulence within the pipe system, leading to more efficient fluid flow and potential energy savings in pumping operations. Moreover, their inherent corrosion resistance, particularly when specified with appropriate liner materials, makes them ideal for handling corrosive chemicals, acids, and alkalis, providing a robust defense against system degradation. This feature is particularly crucial in chemical processing and wastewater treatment, where metallic alternatives would quickly succumb to corrosive media. The adaptability of materials and design in rubber expansion joints ensures a customized solution for nearly any fluid handling challenge, offering unparalleled reliability and long-term cost-effectiveness compared to rigid piping solutions.

Manufacturer Comparison and Tailored Solutions for Rubber Joints

Selecting the right manufacturer for rubber joints is a strategic decision that profoundly impacts system reliability, operational longevity, and total cost of ownership. While many suppliers offer rubber expansion joints, distinguishing between them requires a comprehensive evaluation of their expertise, manufacturing capabilities, quality control processes, and customer support. Leading manufacturers typically possess extensive experience, often spanning several decades, in designing and producing specialized flexible connectors for diverse industrial applications. They invest heavily in R&D to develop new elastomeric compounds with enhanced resistance to temperature, pressure, and aggressive chemicals, and advanced molding techniques for superior product consistency. Key differentiators include adherence to international manufacturing standards (e.g., ISO 9001 certified facilities), verifiable product certifications (e.g., ASME, CE, WRAS), and a robust track record of successful project implementations, often showcased through detailed case studies or client testimonials. A manufacturer's ability to provide comprehensive engineering support, from initial design consultation to post-installation troubleshooting, also signifies their commitment to client success. For specialized products like the JGD41-10/16 Rubber Curved Joints, a manufacturer's deep understanding of fluid dynamics and pipe stress analysis is crucial to ensure optimal performance in complex systems, reflecting their superior authoritativeness in the field.

Beyond standard offerings, the capacity to provide customized solutions is a hallmark of a truly expert manufacturer of general rubber expansion joints. Many industrial applications present unique challenges that off-the-shelf products cannot fully address, requiring tailor-made solutions for specific pressures, temperatures, media, or spatial constraints. A reputable manufacturer will engage in a collaborative process, conducting thorough needs assessments, offering design iterations, and performing finite element analysis (FEA) to validate custom designs before production. This can involve developing bespoke rubber compounds for extreme chemical environments, designing unique flange configurations for non-standard piping, or engineering multi-arch bellows for enhanced movement capabilities. For example, for a complex large-scale water treatment plant, a manufacturer might provide a customized large-diameter rubber expansion joint for pipe with specific pressure ratings and seismic capabilities, ensuring compliance with local building codes and operational safety. Our company, HBY Valves, specializes in delivering such bespoke solutions, leveraging decades of experience in the valve and fitting industry. Our commitment to quality is underscored by rigorous testing, certifications such as ISO 9001, and a comprehensive warranty program, ensuring that clients receive reliable products with exceptional customer support. Our delivery cycles are optimized for efficiency, typically ranging from 4-8 weeks for standard products and slightly longer for highly customized orders, all communicated transparently to ensure timely project completion.

Key Manufacturer Comparison Criteria for Rubber Joints

| Criteria | Leading Manufacturer (e.g., HBY Valves) | Standard Manufacturer |

|---|---|---|

| Certifications | ISO 9001, CE, ASME, API | Basic ISO 9001 (sometimes) |

| R&D Investment | High; continuous material and design innovation | Low; focus on existing designs |

| Customization Capability | Full engineering support, bespoke designs | Limited to minor modifications |

| Quality Control | Multi-stage testing (hydrostatic, vacuum, cycle life), material traceability | Basic visual and pressure tests |

| Technical Support | Pre-sales consultation, installation guidance, post-sales troubleshooting | Limited; primarily sales-focused |

| Warranty & Service Life | Extended warranty, documented 10-15+ years service life | Standard 1-year warranty, shorter expected life |

Frequently Asked Questions (FAQ) about Industrial Rubber Joints

Q1: What is the primary function of a rubber expansion joint in a piping system?

The primary function of a rubber expansion joint is to absorb various types of movement (axial, lateral, angular, torsional) within a piping system, which typically arise from thermal expansion or contraction, seismic activity, ground settlement, or mechanical vibration from connected equipment like pumps and compressors. These movements, if not properly accommodated, can induce significant stress on pipes, flanges, and equipment, leading to premature fatigue, leaks, or even catastrophic failure. Beyond movement absorption, rubber joints also serve to reduce noise transmission, isolate vibration, and compensate for minor misalignments during installation, thus protecting the entire system and extending its operational lifespan. This capability makes general rubber expansion joints an essential component for maintaining system integrity and operational efficiency in demanding industrial environments, ensuring fluid conveyance systems remain robust and reliable over time.

Q2: How do I select the correct rubber expansion joint for my application?

Selecting the correct rubber expansion joint for pipe applications requires a thorough understanding of several critical parameters specific to your system. Key factors to consider include the nominal pipe diameter, the operating temperature range of the conveyed media, the maximum working pressure (and any vacuum conditions), the type of fluid being conveyed (for material compatibility), and the expected types and magnitudes of movement (axial compression/extension, lateral deflection, angular rotation). Additionally, environmental factors like external abrasion, UV exposure, and chemical splash should be evaluated. For example, for a corrosive chemical application, a joint with an EPDM or Viton liner would be more suitable than one with a standard Neoprene liner. Consulting with experienced engineers or the manufacturer's technical team is highly recommended to ensure proper selection, as an undersized or incorrectly specified joint can lead to premature failure and system downtime. Utilizing manufacturer-provided selection guides and material compatibility charts can also aid in making an informed decision, ensuring the optimal performance and longevity of the rubber joint.

Q3: What are the benefits of using JGD41-10/16 Rubber Curved Joints over straight rubber joints?

The JGD41-10/16 Rubber Curved Joints offer distinct advantages over traditional straight rubber joints, particularly in applications with complex piping layouts or where multi-directional movement absorption is critical. Their inherent curved design allows them to efficiently accommodate significant angular and lateral deflections, making them ideal for installations around bends, corners, or in situations where pipe alignment is not perfectly linear. This unique geometry reduces the need for multiple straight joints or complex pipe routing, simplifying system design and potentially lowering installation costs. Furthermore, the curved profile can help to reduce turbulence within the fluid flow, leading to more efficient operation and reduced pressure drop. In scenarios involving large-scale industrial projects where space is at a premium and precise movement compensation is vital, the JGD41-10/16 Curved Joint provides a highly effective and space-saving solution that enhances system flexibility and overall reliability, making it a specialized and superior choice for specific demanding applications.

Q4: What is the typical lifespan and warranty for rubber joints?

The typical lifespan of high-quality industrial rubber joints can range from 10 to 15 years, and in some well-maintained applications, even longer, depending on factors such as operating conditions (temperature, pressure, media), the frequency and magnitude of movements, correct installation, and the quality of the materials and manufacturing process. Products from reputable manufacturers, like HBY Valves, are designed for longevity and rigorous performance. They often come with a standard warranty, typically ranging from 1 to 3 years, covering manufacturing defects. However, it is crucial to note that the actual service life can be significantly influenced by adhering to recommended installation practices, regular inspection schedules, and ensuring the joint is operating within its specified design limits. Over-stressing the joint beyond its rated movement capabilities or exposing it to incompatible media will invariably shorten its lifespan. Always refer to the manufacturer's specific product documentation for detailed warranty information and expected service life under various operating conditions to ensure compliance and maximize investment returns.

Authoritative References and Industry Standards

- Expansion Joint Manufacturers Association (EJMA) Standards: A comprehensive guide for the design, manufacture, and testing of metallic and non-metallic expansion joints, widely adopted globally for ensuring product integrity and performance.

- International Organization for Standardization (ISO) 9001: Quality management systems standard that ensures manufacturers consistently provide products and services that meet customer and regulatory requirements, enhancing trustworthiness.

- American Society for Testing and Materials (ASTM) International Standards: Provides widely accepted material and testing specifications for rubber and elastomeric compounds, ensuring the quality and consistency of raw materials used in rubber joint manufacturing.

- American Water Works Association (AWWA) Standards: Specifically for water supply and treatment applications, setting benchmarks for components like rubber expansion joints used in municipal water infrastructure.

- Hydraulic Institute (HI) Standards: Offers guidelines and best practices for pumps and pumping systems, often referencing the importance of flexible connectors like rubber joints for vibration isolation and pipe stress reduction.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025