Feb . 17, 2025 14:42

Back to list

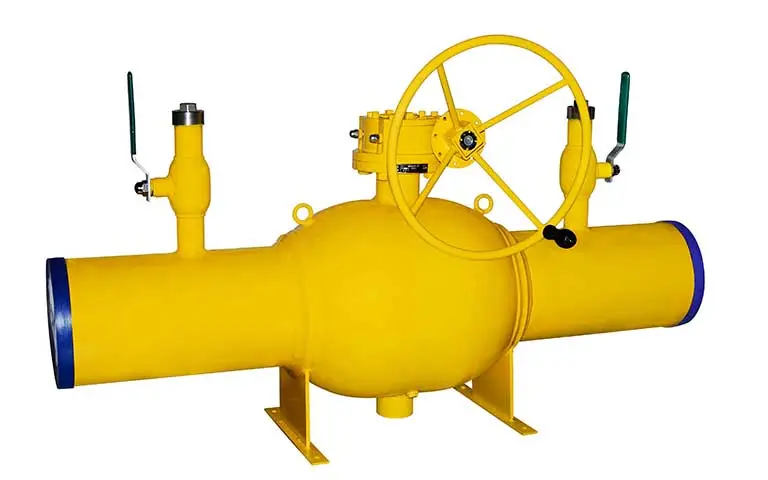

Q11f-16p Stainless Steel Two-piece Ball Valve

When it comes to industrial applications requiring reliable fluid control, the China 3 piece ball valve emerges as an indispensable piece of equipment. These valves, known for their robustness and reliability, have been gaining recognition worldwide. Understanding their functionality, manufacturing excellence, and particular applications can greatly enhance operational efficiency and safety in various industries.

The versatility of these valves extends beyond industrial scopes. In pressure-sensitive environments, the ability to control fluid flow with precision reduces the risk of system overpressure, safeguarding against potential hazards. The ergonomic design of the 3 piece ball valve lends itself to easy manual operation, while automation options enhance operational efficiency in more complex systems where remote operation is a necessity. China’s authority in producing these valves stems not only from advanced manufacturing capabilities but also from deep market insights and customer-oriented strategies. Chinese manufacturers often provide customizable options that cater to specific industry requirements, positioning themselves as trusted partners in global supply chains. This ability to provide tailored solutions, coupled with competitive pricing, enhances trustworthiness among global clients. In an era where industrial reliability and safety are paramount, the China 3 piece ball valve stands out as an essential component in fluid control technology. The synthesis of expert design, innovative material usage, and a customer-focused approach makes these valves a fixture in industries requiring precision and efficiency. For professionals in need of a reliable solution for complex fluid control challenges, these valves represent a combination of engineering excellence and practical application. By choosing a 3 piece ball valve, industries ensure operational continuity, product integrity, and above all, a promise of reliability that modern industrial operations consistently demand.

The versatility of these valves extends beyond industrial scopes. In pressure-sensitive environments, the ability to control fluid flow with precision reduces the risk of system overpressure, safeguarding against potential hazards. The ergonomic design of the 3 piece ball valve lends itself to easy manual operation, while automation options enhance operational efficiency in more complex systems where remote operation is a necessity. China’s authority in producing these valves stems not only from advanced manufacturing capabilities but also from deep market insights and customer-oriented strategies. Chinese manufacturers often provide customizable options that cater to specific industry requirements, positioning themselves as trusted partners in global supply chains. This ability to provide tailored solutions, coupled with competitive pricing, enhances trustworthiness among global clients. In an era where industrial reliability and safety are paramount, the China 3 piece ball valve stands out as an essential component in fluid control technology. The synthesis of expert design, innovative material usage, and a customer-focused approach makes these valves a fixture in industries requiring precision and efficiency. For professionals in need of a reliable solution for complex fluid control challenges, these valves represent a combination of engineering excellence and practical application. By choosing a 3 piece ball valve, industries ensure operational continuity, product integrity, and above all, a promise of reliability that modern industrial operations consistently demand.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025