ABASAMBANYI B'IBICURUZWA:

| Diameter (mm) |

L | D1 | D | ||||||

| PN10 / 16 | PN25 / 40 | PN10 | PN16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

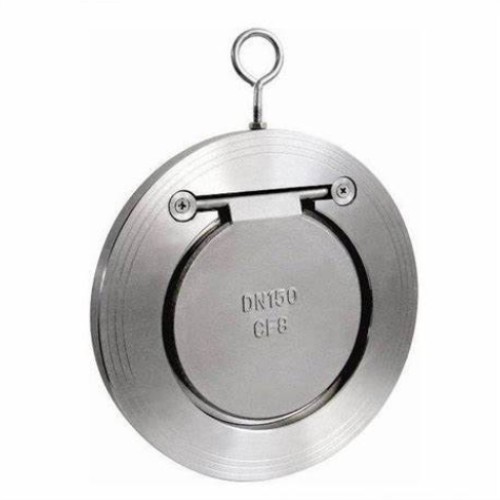

| Izina ry'igice | ibikoresho | ||

| Umubiri / bonnet | WCB / stainless steel | ||

| Disiki | WCB / stainless steel | ||

| Impeta | NBR / EPDM / PTFE / steel |

| icyitegererezo | Umuvuduko w'izina (mpa) |

igitutu cy'ikizamini | ubushyuhe bukwiye | Uburyo bukoreshwa | |||||

| Imbaraga (amazi) | Ikidodo (amazi) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Inama:

1.Imiterere yuzuye, igishushanyo mbonera, icyuma cyiza cya valve, inzira yoroshye.

2.Gukoresha ibipapuro byoroshye byo gupakira, gufunga byizewe, urumuri kandi rworoshye

Porogaramu:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.Dufite tekinoroji yo gutunganya umucanga cyangwa Precision, Turashobora rero nkigishushanyo cyawe cyo gushushanya no gukora.

2. Ibirango byabakiriya birahari bikozwe kumubiri wa valve.

3. Gukina kwacu kwose hamwe nubushyuhe mbere yo Gutunganya.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Ubwoko bwa valve dusanzwe dukoresha Amashashi gupakira, Turashobora kandi dukurikije ibyifuzo byabakiriya byihariye.

COMPANY ADVANTAGES:

-

1.Turi uruganda Kuva 1992.

1.Turi uruganda Kuva 1992. -

2.CE, API, ISO byemewe.

2.CE, API, ISO byemewe. -

3.Gutanga vuba.

3.Gutanga vuba. -

4.Gabanya igiciro gifite ubuziranenge.

4.Gabanya igiciro gifite ubuziranenge. -

5.Ikipe y'umwuga!

5.Ikipe y'umwuga!