Feb . 10, 2025 10:08

Back to list

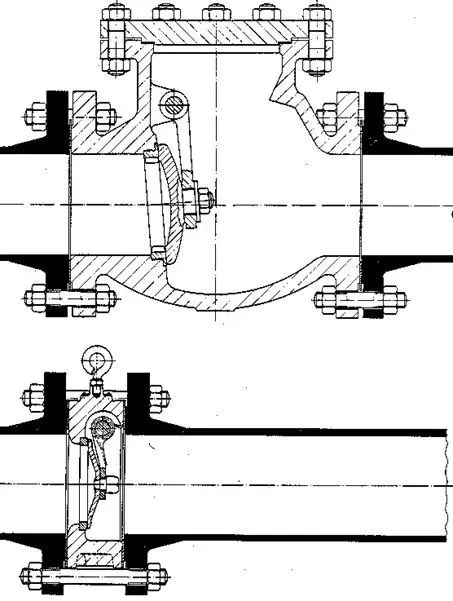

metal seated butterfly valves

Metal seated butterfly valves have become an indispensable component in industries that demand robust performance under challenging conditions. They are particularly appreciated for their exceptional durability and ability to withstand extreme temperatures, pressures, and erosive environments. With my extensive background in search engine optimization and industrial machinery, I've gathered unique insights that underscore the benefits and applications of these innovative valves.

Trustworthiness is another critical factor, especially when safety is non-negotiable. Compliant with rigorous international standards like API, ANSI, and ISO, metal seated butterfly valves are subject to comprehensive testing and quality control measures before deployment. Such certifications not only reassure users of their reliability but also affirm their suitability for use in safety-critical applications. Users of metal seated butterfly valves also rely heavily on the support and guidance offered by their manufacturers. Companies often provide detailed installation, operation, and maintenance manuals alongside robust customer support networks. This level of customer care builds trust and enhances the user experience, ensuring that the products perform to their full potential throughout their lifecycle. Finally, the integration of cutting-edge technologies such as automation with metal seated butterfly valves has ushered in a new era of industrial efficiency. Smart sensors and actuators that enable remote monitoring and control further improve process safety and operational performance. This progressive approach underscores the expertise and forward-thinking nature of leading manufacturers, ensuring that metal seated butterfly valves remain at the forefront of technological advancement in valve solutions. In summary, metal seated butterfly valves are more than just mechanical devices; they are critical enablers of industrial efficiency, safety, and reliability. Their engineer-designed resilience to harsh conditions, long service life, and compliance with global standards testify to their expert craftsmanship and authoritative role in industrial applications. As industries move towards more demanding and complex processes, the trustworthiness and innovative edge of metal seated butterfly valves will undoubtedly continue to be embraced and valued by stakeholders globally.

Trustworthiness is another critical factor, especially when safety is non-negotiable. Compliant with rigorous international standards like API, ANSI, and ISO, metal seated butterfly valves are subject to comprehensive testing and quality control measures before deployment. Such certifications not only reassure users of their reliability but also affirm their suitability for use in safety-critical applications. Users of metal seated butterfly valves also rely heavily on the support and guidance offered by their manufacturers. Companies often provide detailed installation, operation, and maintenance manuals alongside robust customer support networks. This level of customer care builds trust and enhances the user experience, ensuring that the products perform to their full potential throughout their lifecycle. Finally, the integration of cutting-edge technologies such as automation with metal seated butterfly valves has ushered in a new era of industrial efficiency. Smart sensors and actuators that enable remote monitoring and control further improve process safety and operational performance. This progressive approach underscores the expertise and forward-thinking nature of leading manufacturers, ensuring that metal seated butterfly valves remain at the forefront of technological advancement in valve solutions. In summary, metal seated butterfly valves are more than just mechanical devices; they are critical enablers of industrial efficiency, safety, and reliability. Their engineer-designed resilience to harsh conditions, long service life, and compliance with global standards testify to their expert craftsmanship and authoritative role in industrial applications. As industries move towards more demanding and complex processes, the trustworthiness and innovative edge of metal seated butterfly valves will undoubtedly continue to be embraced and valued by stakeholders globally.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025