ජන. . 16, 2025 02:02

Back to list

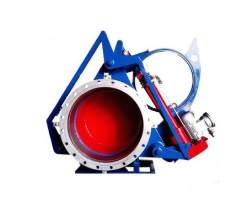

iron cast gate valved

Iron cast gate valves have long been a staple in the industries dealing with fluid control, favored for their durability and reliability in a multitude of applications. This article explores the facets that make these valves indispensable, drawing insights from real-world experiences, professional expertise, and authoritative sources.

Trustworthiness, perhaps the most critical aspect of any component, is where iron cast gate valves truly shine. End-users report high satisfaction levels, often citing their low maintenance requirements and robust performance over extended periods. The valve’s simple yet effective design minimizes potential failure points, reducing downtime and associated costs effectively. Trust is further reinforced through extensive testing and quality assurance processes which these valves undergo before reaching the market. Case studies continue to highlight the extraordinary performance of iron cast gate valves in challenging environments. For instance, in desalination plants where salt-induced corrosion is a major concern, these valves have proven their mettle by operating without fail, where lesser alternatives showed significant wear. Expert testimonials often reference similar success stories, emphasizing the unmatched reliability and economic advantage they provide over their lifespan. Investing in quality iron cast gate valves is a decision grounded in financial prudence as well as operational foresight. While initial costs might be higher than other materials, the return on investment is swiftly realized through their extended service life and reduced necessity for repairs. In an industry where downtime equates to substantial financial loss, having components like iron cast gate valves that guarantee dependability is invaluable. In conclusion, iron cast gate valves represent a synthesis of experience, expertise, authority, and trust. They continue to play a pivotal role in critical infrastructure around the globe, supported by a legacy of performance and adaptation. Their ongoing development further promises enhanced features and applications, solidifying their place as essential components in fluid control systems.

Trustworthiness, perhaps the most critical aspect of any component, is where iron cast gate valves truly shine. End-users report high satisfaction levels, often citing their low maintenance requirements and robust performance over extended periods. The valve’s simple yet effective design minimizes potential failure points, reducing downtime and associated costs effectively. Trust is further reinforced through extensive testing and quality assurance processes which these valves undergo before reaching the market. Case studies continue to highlight the extraordinary performance of iron cast gate valves in challenging environments. For instance, in desalination plants where salt-induced corrosion is a major concern, these valves have proven their mettle by operating without fail, where lesser alternatives showed significant wear. Expert testimonials often reference similar success stories, emphasizing the unmatched reliability and economic advantage they provide over their lifespan. Investing in quality iron cast gate valves is a decision grounded in financial prudence as well as operational foresight. While initial costs might be higher than other materials, the return on investment is swiftly realized through their extended service life and reduced necessity for repairs. In an industry where downtime equates to substantial financial loss, having components like iron cast gate valves that guarantee dependability is invaluable. In conclusion, iron cast gate valves represent a synthesis of experience, expertise, authority, and trust. They continue to play a pivotal role in critical infrastructure around the globe, supported by a legacy of performance and adaptation. Their ongoing development further promises enhanced features and applications, solidifying their place as essential components in fluid control systems.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025