LITLHAKISO TSA LITŠOANTŠISO:

| Bophara ba lebitso (mm) |

L | D1 | D | ||||||

| PN10 / 16 | PN25 / 40 | PN10 | PN16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

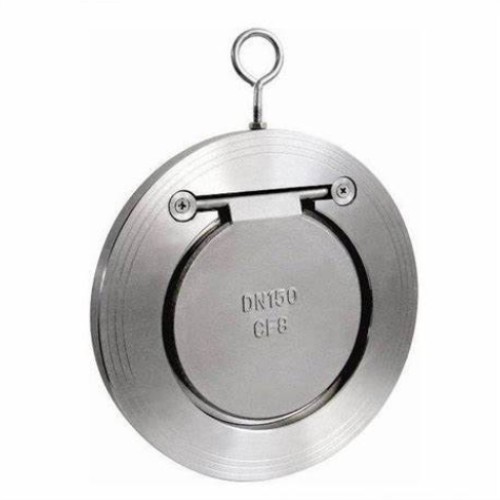

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

| Karolo Lebitso | thepa | ||

| Mmele/ Bonnet | WCB / stainless steel | ||

| Diski | WCB / stainless steel | ||

| Lesale la ho tiisa | NBR / EPDM / PTFE / steel |

| mohlala | Khatello ea lebitso (mpa) |

khatello ea teko | mocheso o loketseng | Seaplane se sebetsang | |||||

| Matla (metsi) | Tiisitsoe (metsi) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Malebela:

1.Sebopeho sa Compact, moralo o utloahalang, ho tiea ha valve hantle, tsela e boreleli.

2.Tšebeliso ea ho paka ka graphite e feto-fetohang, ho tiisa ho ka tšeptjoang, ts'ebetso e bobebe le e bonolo

Lisebelisoa:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.Re na le thekenoloji ea Sand kapa Precision casting, kahoo re ka khona ho etsa moralo oa hau oa ho taka le tlhahiso.

Li-logos tsa 2.Customers li fumaneha ka har'a 'mele oa valve.

3. Lits'ebetso tsohle tsa rona tsa ho lahlela ka mokhoa oa ho futhumatsa pele ho Processing.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Belofo e mosa eo re atisang ho e sebelisa Mekotla ho paka, Re boetse re ka ho ea ka likopo tse itseng moreki.

COMPANY ADVANTAGES:

-

1.Re moetsi Ho tloha 1992.

1.Re moetsi Ho tloha 1992. -

2.CE, API, ISO e amohetsoe.

2.CE, API, ISO e amohetsoe. -

3.Ho fana ka potlako.

3.Ho fana ka potlako. -

4.Theko e tlaase e nang le boleng bo phahameng.

4.Theko e tlaase e nang le boleng bo phahameng. -

5.Sehlopha sa mosebetsi oa professional!

5.Sehlopha sa mosebetsi oa professional!