MAHSULOT PARAMETRLARI:

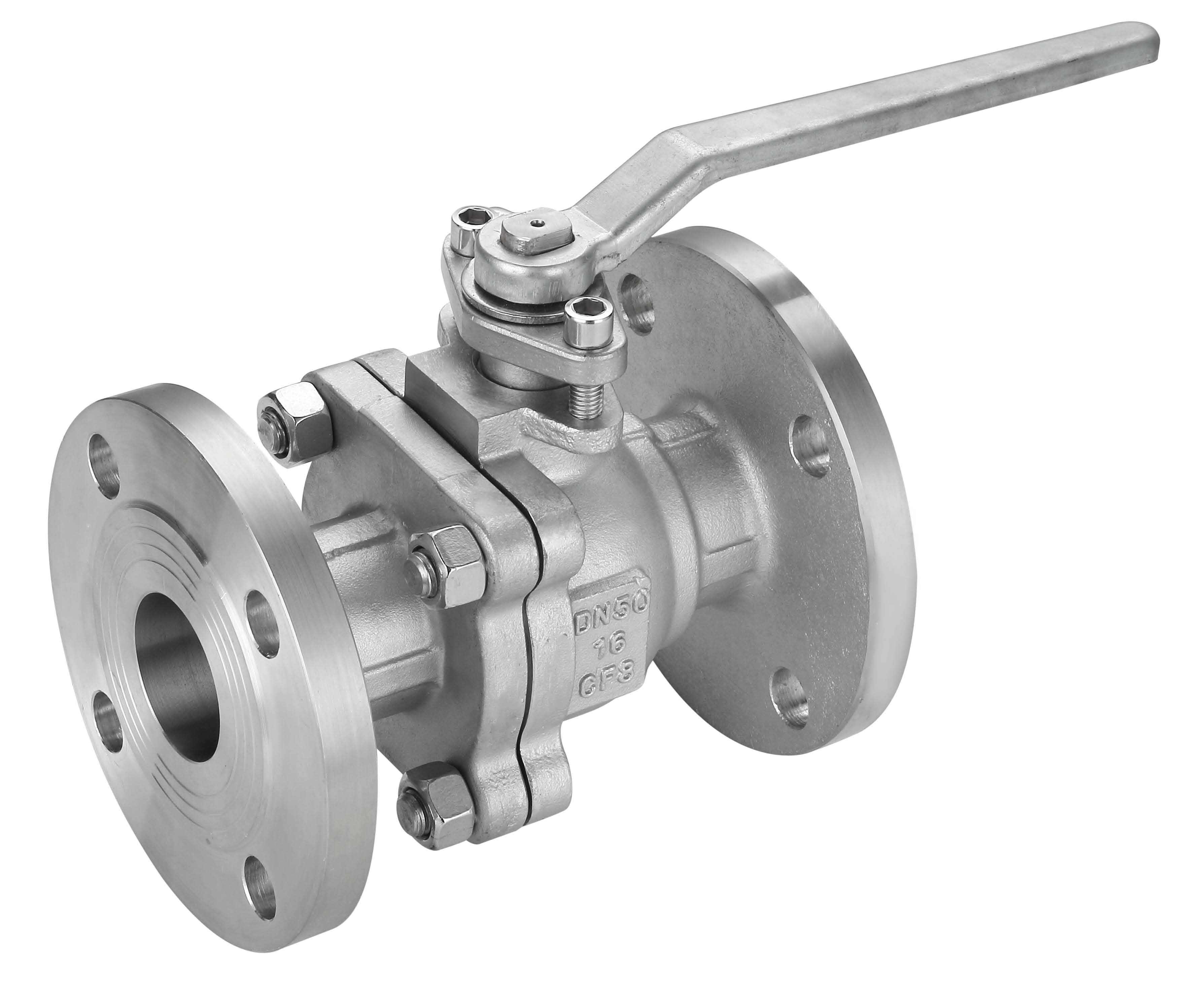

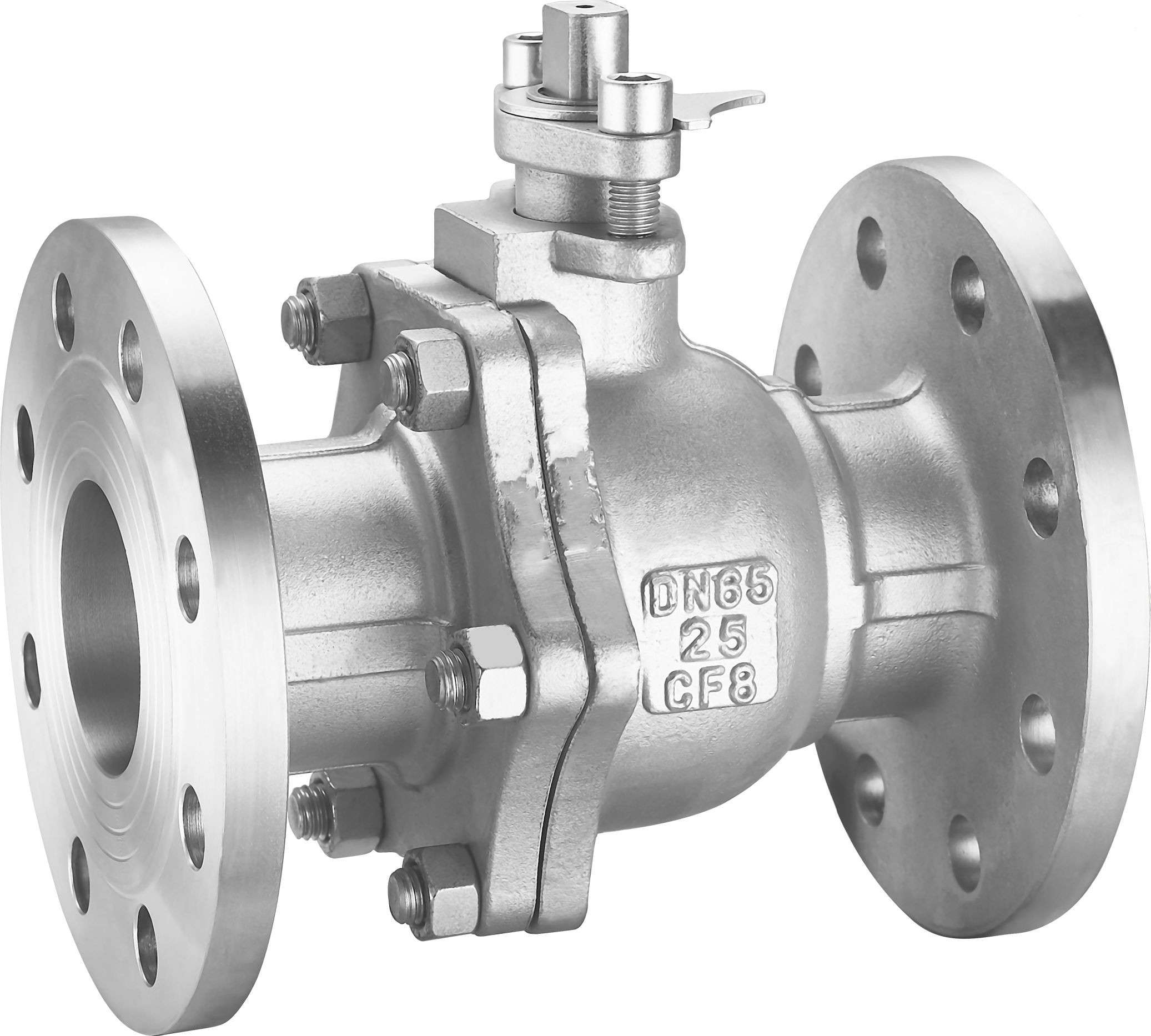

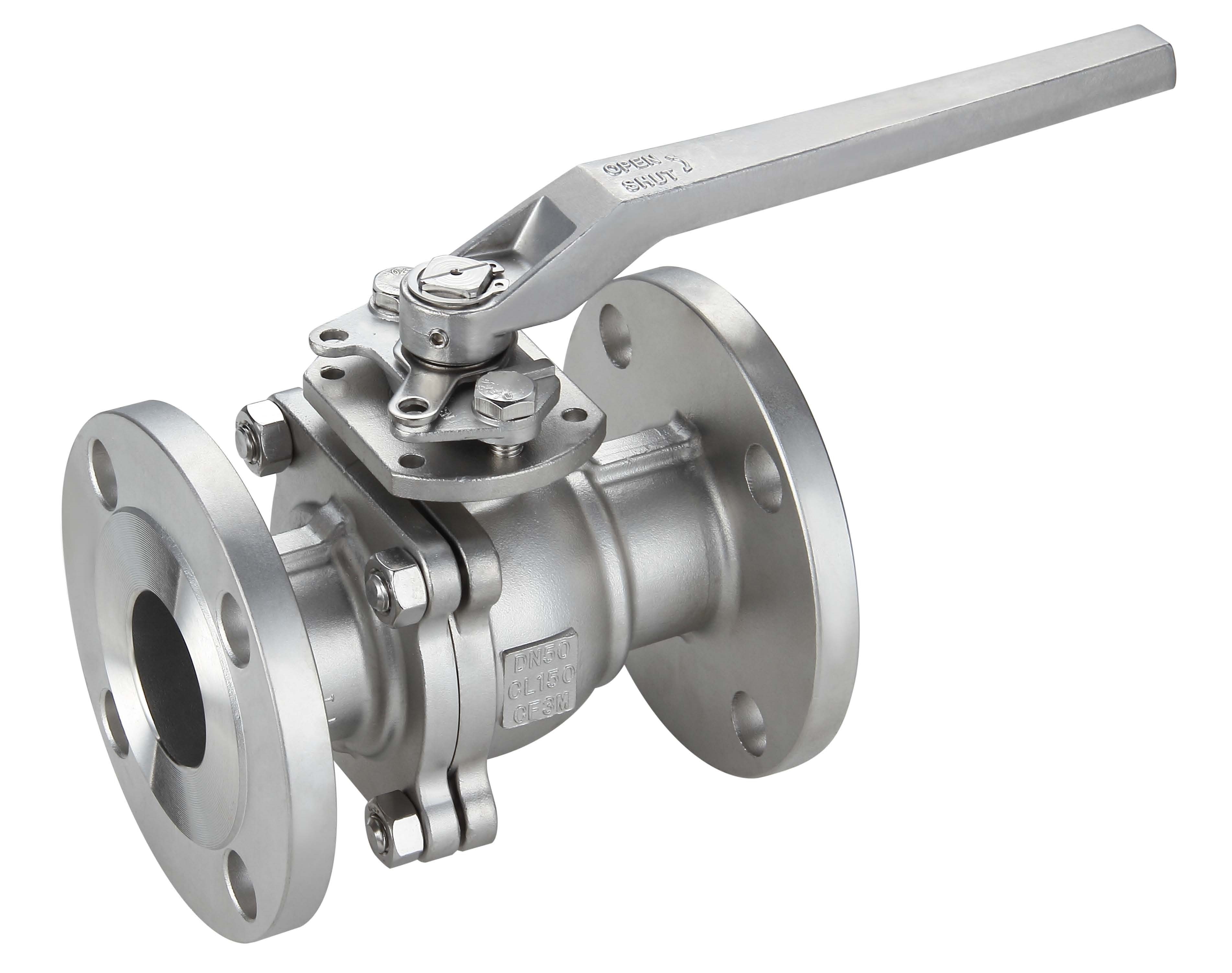

ANSI suzuvchi sharli klapan Asosiy qismlarning materiali

|

ANSI suzuvchi sharli klapan Asosiy qismlarning materiali |

|

|

Qism nomi |

material |

|

Kuzov / kapot |

ASTM A216 WCB, CF8, CF8M |

|

to'p |

ASTM A105, F304, F316 |

|

Vana poyasi |

ASTM A182 F6a, F304, F316 |

|

Shlangi |

PTFE |

ANSI suzuvchi sharli klapan Q41F ishlash xususiyatlari

|

ANSI suzuvchi sharli klapan Q41F ishlash xususiyatlari |

|||||

|

model |

Nominal bosim |

Sinov bosimi (mpa) suv |

to'g'ri harorat |

Amaldagi vosita |

|

|

kuch |

muhr |

||||

|

Q41F-150LB |

150 |

3.00 |

2.20 |

≤150 ℃ |

Suv, bug ', yog' va boshqalar. |

|

Q41F-300LB |

300 |

7.50 |

5.50 |

||

|

Q41F-600LB |

600 |

15.00 |

11.00 |

||

ANSI suzuvchi sharli klapan Q41F o'lchamlari va ulanish o'lchamlari

|

ANSI suzuvchi sharli klapan Q41F o'lchamlari va ulanish o'lchamlari |

|||||||

|

model |

Nominal diametri |

Hajmi (mm) |

|||||

|

L |

D |

D1 |

D2 |

bf |

z-φd |

||

|

Q41F-150LB |

1/2 " |

108 |

90 |

60.5 |

35 |

11-2 |

4 * φ16 |

|

3/4 " |

117 |

100 |

70 |

43 |

13.5-2 |

4 * φ16 |

|

|

1" |

127 |

110 |

79.5 |

51 |

15-2 |

4 * φ16 |

|

|

1 1/4 " |

140 |

115 |

89 |

63.5 |

16.5-2 |

4 * φ16 |

|

|

1 1/2 " |

165 |

125 |

98.5 |

73 |

18-2 |

4 * φ16 |

|

|

2" |

178 |

150 |

121 |

92 |

19.5-2 |

4 * φ19 |

|

|

2 1/2 " |

190 |

180 |

140 |

105 |

23-2 |

4 * φ19 |

|

|

3 " |

203 |

190 |

152.5 |

127 |

24.5-2 |

4 * φ19 |

|

|

4 " |

229 |

230 |

190.5 |

157 |

24.5-2 |

8 * φ19 |

|

|

6 " |

394 |

280 |

241.5 |

216 |

26-2 |

8 * φ22 |

|

|

8" |

457 |

345 |

298.5 |

270 |

29-2 |

8 * φ22 |

|

|

Q41F-300LB |

1/2 " |

140 |

95 |

66.5 |

35 |

15-2 |

4 * φ16 |

|

3/4 " |

152 |

115 |

82.5 |

43 |

16.5-2 |

4 * φ19 |

|

|

1" |

165 |

125 |

89 |

51 |

18-2 |

4 * φ19 |

|

|

1 1/4 " |

178 |

135 |

98.5 |

63.5 |

19.5-2 |

4 * φ19 |

|

|

1 1/2 " |

190 |

155 |

114.5 |

73 |

21-2 |

4 * φ22 |

|

|

2" |

216 |

165 |

127 |

92 |

23-2 |

8 * φ19 |

|

|

2 1/2 " |

241 |

190 |

149 |

105 |

26-2 |

8 * φ22 |

|

|

3 " |

282 |

210 |

168.5 |

127 |

29-2 |

8 * φ22 |

|

|

4 " |

305 |

255 |

200 |

157 |

32-2 |

8 * φ22 |

|

|

6 " |

403 |

320 |

270 |

216 |

37-2 |

12 * φ22 |

|

|

8" |

502 |

380 |

330 |

270 |

42-2 |

12 * φ25 |

|

Ilovalar:

Ushbu valf gazni bostirish uchun emas, balki to'liq ochiq va to'liq yopiq bo'lgan barcha turdagi quvurlar uchun javob beradi.

Kompaniyaning afzalliklari:

-

1.Biz 1992 yildan beri ishlab chiqaruvchilarmiz.

1.Biz 1992 yildan beri ishlab chiqaruvchilarmiz. -

2.CE, API, ISO tasdiqlangan.

2.CE, API, ISO tasdiqlangan. -

3. Tez yetkazib berish.

3. Tez yetkazib berish. -

4.Yuqori sifat bilan past narx.

4.Yuqori sifat bilan past narx. -

5.Professional ish jamoasi!

5.Professional ish jamoasi!

Mahsulot afzalliklari:

1.Bizda qum yoki nozik quyish texnologiyasi mavjud, shuning uchun biz sizning chizilgan dizayningiz va ishlab chiqarishingiz mumkin.

2.Mijozlarning logotiplari vana tanasiga quyiladi.

3. Qayta ishlashdan oldin temperlash tartibi bilan barcha quymalarimiz.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7. Biz odatda yog'och qutilarni qadoqlash uchun ishlatamiz, biz ham shunga ko'ra qila olamiz

mijozning maxsus so'rovlari.