IIPARAMETHA ZEMVELISO:

| Idayamitha yegama (mm) |

L | D1 | D | ||||||

| PN10 / 16 | PN25 / 40 | PN10 | PN16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

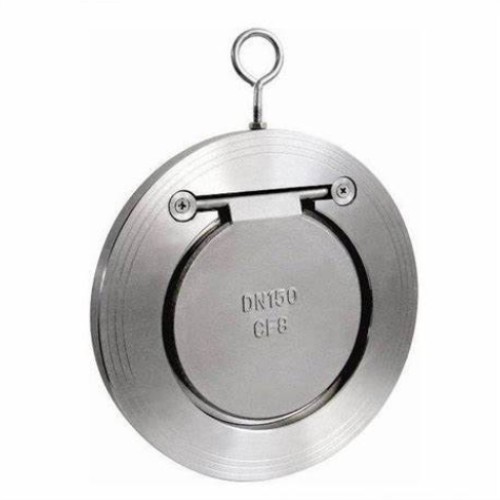

| Igama lenxalenye | impahla | ||

| Umzimba / ibhonethi | WCB / stainless steel | ||

| Icwecwe | WCB / stainless steel | ||

| Umsesane wokutywina | NBR / EPDM / PTFE / steel |

| imodeli | Uxinzelelo lwegama (Mpa) |

uvavanyo loxinzelelo | ubushushu obufanelekileyo | Isiphakathi esisebenzayo | |||||

| Amandla (amanzi) | Itywiniwe (amanzi) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Iingcebiso:

1.Ulwakhiwo olubambeneyo, uyilo olunengqiqo, ukuqina kwevalve elungileyo, ukudlula okugudileyo.

I-2.Ukusetyenziswa kwe-flexible graphite packing, ukutywinwa okuthembekileyo, ukukhanya kunye nokusebenza okuguquguqukayo

Usetyenziso:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.Sine-Sand okanye i-Precision casting technology, ngoko sinako njengoyilo lwakho lomzobo kunye nemveliso.

2.Iilogo zabathengi ziyafumaneka ngokuphoswa kumzimba wevalvu.

3. Konke ukuphosa kwethu ngenkqubo yokuthambisa ngaphambi koKusetyenzwa.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Ivalve enobubele esidla ngokuyisebenzisa Iingxowa ukupakisha, Singakwazi kwakhona ngokwezicelo zomthengi othile.

COMPANY ADVANTAGES:

-

1.Singumenzi Ukusukela ngo-1992.

1.Singumenzi Ukusukela ngo-1992. -

2.CE,API,ISO evunyiweyo.

2.CE,API,ISO evunyiweyo. -

3.Ukuhanjiswa ngokukhawuleza.

3.Ukuhanjiswa ngokukhawuleza. -

I-4.Ixabiso eliphantsi elinomgangatho ophezulu.

I-4.Ixabiso eliphantsi elinomgangatho ophezulu. -

5.Iqela lomsebenzi wobuGcisa!

5.Iqela lomsebenzi wobuGcisa!