IMIPHAKATHI YOMKHIQIZO:

| Ububanzi bokuzisholo (mm) |

L | D1 | D | ||||||

| I-PN10 / 16 | PN25 / 40 | I-PN10 | I-PN16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

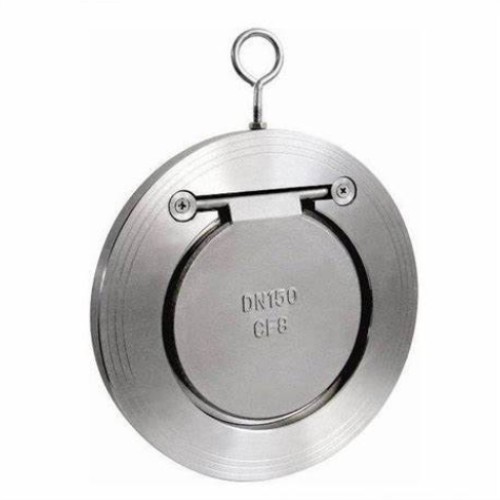

| Ingxenye Igama | impahla | ||

| Umzimba / ibhonethi | WCB / stainless steel | ||

| Idiski | WCB / stainless steel | ||

| Indandatho yokuvala | NBR / EPDM / PTFE / steel |

| imodeli | Ingcindezi yamagama (impa) |

ingcindezi yokuhlola | izinga lokushisa elifanele | Okumaphakathi okusebenzayo | |||||

| Amandla (amanzi) | Kuvaliwe (amanzi) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Amathiphu:

I-1.Isakhiwo esihlangene, ukuklama okunengqondo, ukuqina kwe-valve okuhle, ukuhamba okubushelelezi.

I-2.Ukusetshenziswa kwe-flexible graphite packing, ukubekwa uphawu okuthembekile, ukukhanya nokusebenza okuguquguqukayo

Izicelo:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

I-1.Sine-Sand noma ubuchwepheshe be-Precision casting, Ngakho-ke singakwazi njengomklamo wakho wokudweba nokukhiqiza.

Ama-logo we-2.Customers' ayatholakala ngokusakazwa emzimbeni wevalvu.

3. Konke ukusakaza kwethu ngenqubo yokuthambisa ngaphambi kokucubungula.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.I-valve enomusa esivame ukuyisebenzisa Izikhwama ukupakisha, Singakwazi futhi ngokuvumelana nezicelo zekhasimende ezithile.

COMPANY ADVANTAGES:

-

1.Singabakhi Kusukela ngo-1992.

1.Singabakhi Kusukela ngo-1992. -

2.CE,API,ISO kuvunyiwe.

2.CE,API,ISO kuvunyiwe. -

3.Ukulethwa okusheshayo.

3.Ukulethwa okusheshayo. -

I-4.Intengo ephansi enekhwalithi ephezulu.

I-4.Intengo ephansi enekhwalithi ephezulu. -

5.Ithimba Lomsebenzi Wobungcweti!

5.Ithimba Lomsebenzi Wobungcweti!