IMIPHAKATHI YOMKHIQIZO:

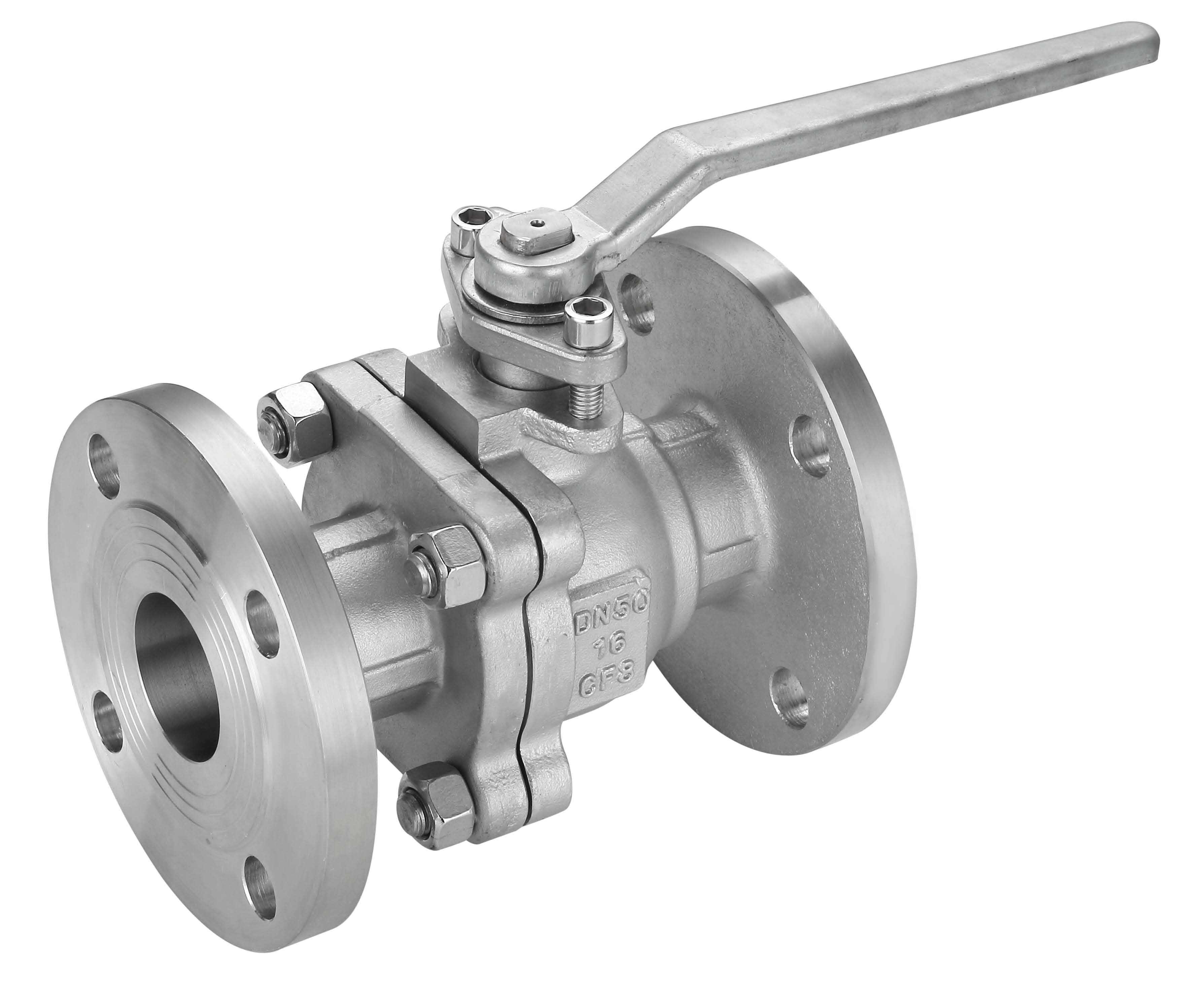

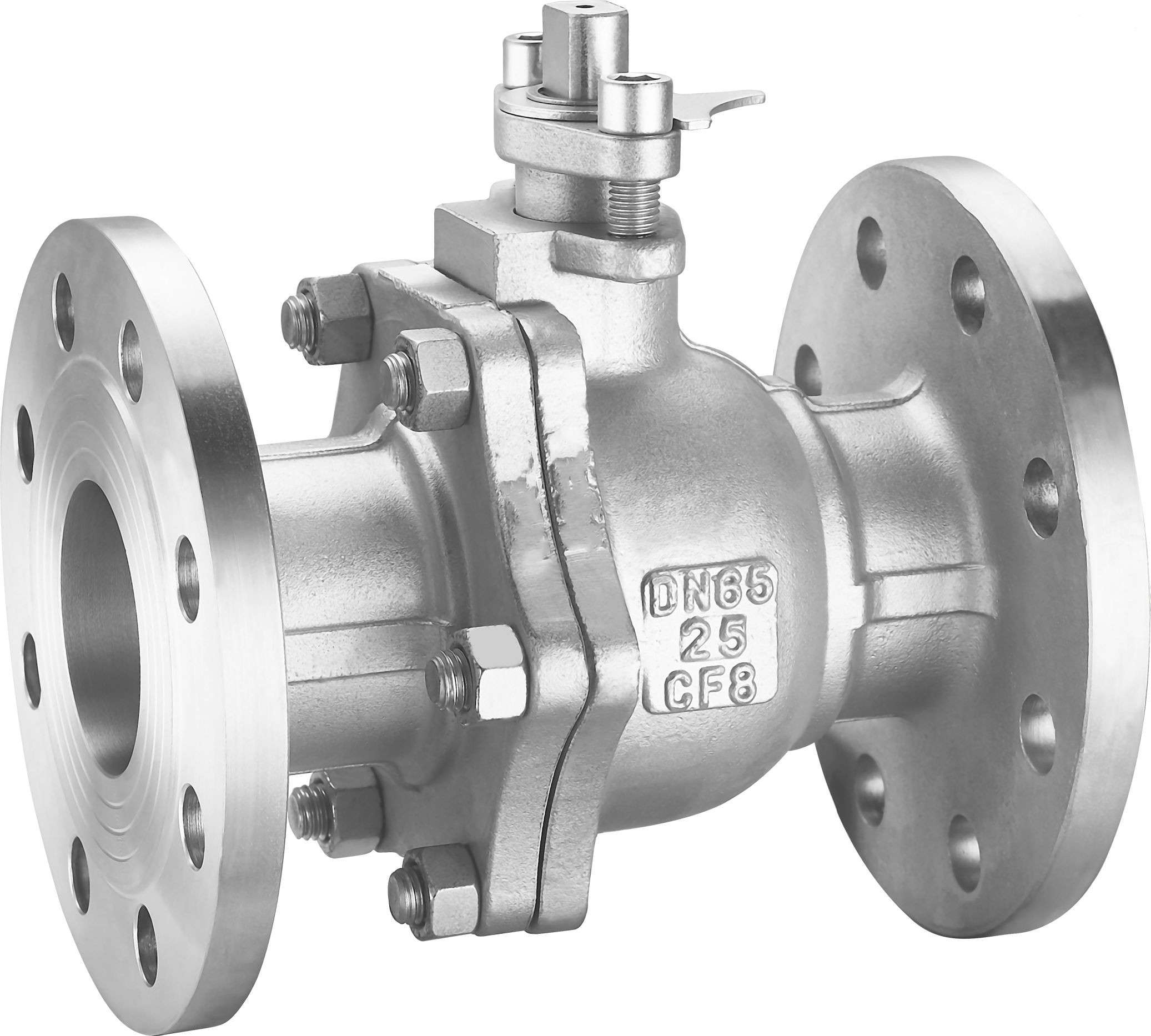

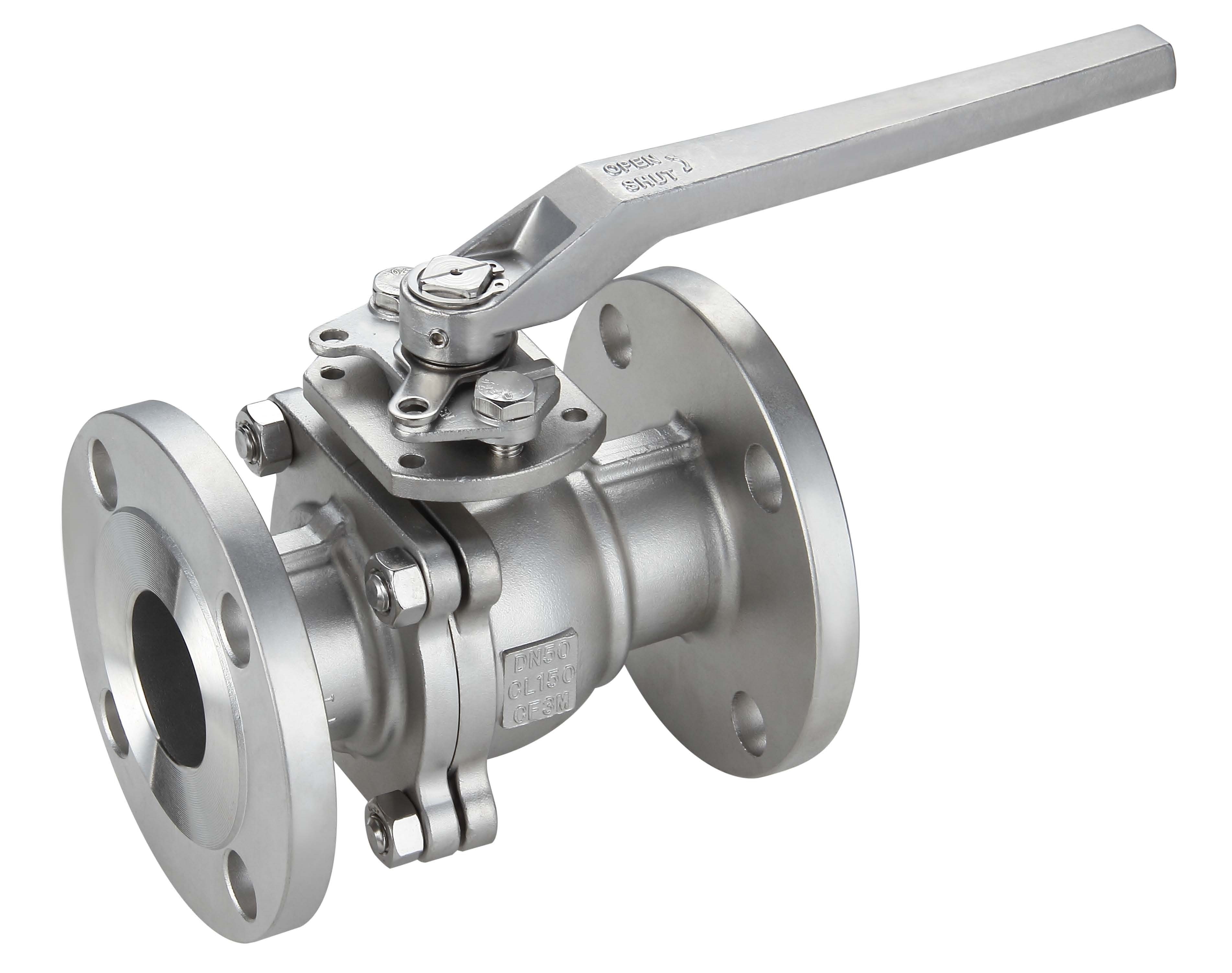

I-ANSI Floating Ball Valve Material yezingxenye eziyinhloko

|

I-ANSI Floating Ball Valve Material yezingxenye eziyinhloko |

|

|

Ingxenye Igama |

impahla |

|

Umzimba / ibhonethi |

I-ASTM A216 WCB, CF8, CF8M |

|

ibhola |

I-ASTM A105, F304, F316 |

|

Isiqu se-valve |

I-ASTM A182 F6a, F304, F316 |

|

I-Gasket |

I-PTFE |

Ukucaciswa kokusebenza kwe-ANSI Floating Ball Valve Q41F

|

Ukucaciswa kokusebenza kwe-ANSI Floating Ball Valve Q41F |

|||||

|

imodeli |

Ingcindezi yamagama |

Ingcindezi yokuhlola (mpa) amanzi |

izinga lokushisa elifanele |

Okumaphakathi okusebenzayo |

|

|

amandla |

uphawu |

||||

|

I-Q41F-150LB |

150 |

3.00 |

2.20 |

≤150 ℃ |

Amanzi, umusi, uwoyela, njll. |

|

I-Q41F-300LB |

300 |

7.50 |

5.50 |

||

|

I-Q41F-600LB |

600 |

15.00 |

11.00 |

||

I-ANSI i-valve yebhola elintantayo engu-Q41F ubukhulu nobukhulu bokuxhumana

|

I-ANSI i-valve yebhola elintantayo engu-Q41F ubukhulu nobukhulu bokuxhumana |

|||||||

|

imodeli |

Ububanzi bokuzisholo |

Usayizi (mm) |

|||||

|

L |

D |

D1 |

D2 |

bf |

z-φd |

||

|

I-Q41F-150LB |

1/2 " |

108 |

90 |

60.5 |

35 |

11-2 |

4 * φ16 |

|

3/4 " |

117 |

100 |

70 |

43 |

13.5-2 |

4 * φ16 |

|

|

1" |

127 |

110 |

79.5 |

51 |

15-2 |

4 * φ16 |

|

|

1 1/4 " |

140 |

115 |

89 |

63.5 |

16.5-2 |

4 * φ16 |

|

|

1 1/2 " |

165 |

125 |

98.5 |

73 |

18-2 |

4 * φ16 |

|

|

2" |

178 |

150 |

121 |

92 |

19.5-2 |

4 * φ19 |

|

|

2 1/2 " |

190 |

180 |

140 |

105 |

23-2 |

4 * φ19 |

|

|

3 " |

203 |

190 |

152.5 |

127 |

24.5-2 |

4 * φ19 |

|

|

4 " |

229 |

230 |

190.5 |

157 |

24.5-2 |

8 * φ19 |

|

|

6 " |

394 |

280 |

241.5 |

216 |

26-2 |

8 * φ22 |

|

|

8" |

457 |

345 |

298.5 |

270 |

29-2 |

8 * φ22 |

|

|

I-Q41F-300LB |

1/2 " |

140 |

95 |

66.5 |

35 |

15-2 |

4 * φ16 |

|

3/4 " |

152 |

115 |

82.5 |

43 |

16.5-2 |

4 * φ19 |

|

|

1" |

165 |

125 |

89 |

51 |

18-2 |

4 * φ19 |

|

|

1 1/4 " |

178 |

135 |

98.5 |

63.5 |

19.5-2 |

4 * φ19 |

|

|

1 1/2 " |

190 |

155 |

114.5 |

73 |

21-2 |

4 * φ22 |

|

|

2" |

216 |

165 |

127 |

92 |

23-2 |

8 * φ19 |

|

|

2 1/2 " |

241 |

190 |

149 |

105 |

26-2 |

8 * φ22 |

|

|

3 " |

282 |

210 |

168.5 |

127 |

29-2 |

8 * φ22 |

|

|

4 " |

305 |

255 |

200 |

157 |

32-2 |

8 * φ22 |

|

|

6 " |

403 |

320 |

270 |

216 |

37-2 |

12 * φ22 |

|

|

8" |

502 |

380 |

330 |

270 |

42-2 |

12 * φ25 |

|

Izicelo:

Le valve ifanele zonke izinhlobo zamapayipi avuleke ngokugcwele futhi avaleke ngokugcwele, hhayi ukuphusha.

Izinzuzo zenkampani:

-

1.Singabakhi Kusukela ngo-1992.

1.Singabakhi Kusukela ngo-1992. -

2.CE,API,ISO kuvunyiwe.

2.CE,API,ISO kuvunyiwe. -

3.Ukulethwa okusheshayo.

3.Ukulethwa okusheshayo. -

I-4.Intengo ephansi enekhwalithi ephezulu.

I-4.Intengo ephansi enekhwalithi ephezulu. -

5.Ithimba Lomsebenzi Wobungcweti!

5.Ithimba Lomsebenzi Wobungcweti!

Izinzuzo Zomkhiqizo:

I-1.Sine-Sand noma ubuchwepheshe be-Precision casting, Ngakho-ke singakwazi njengomklamo wakho wokudweba nokukhiqiza.

Ama-logo we-2.Customers' ayatholakala ngokusakazwa emzimbeni wevalvu.

3. Konke ukusakaza kwethu ngenqubo yokuthambisa ngaphambi kokucubungula.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7.I-valve enomusa sivame ukusebenzisa amacala e-Wooden ukupakisha, Singakwazi futhi ngokusho

izicelo zekhasimende ezithile.