NGA TAATA HUA:

| Te diameter ingoa (mm) |

L | D1 | D | ||||||

| PN10 / 16 | PN25 / 40 | PN10 | PN16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

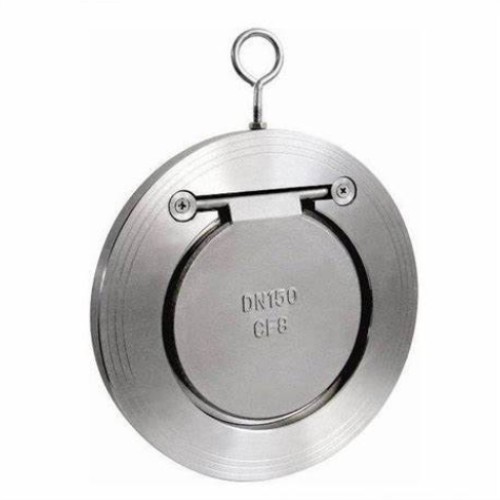

| Ingoa Wāhanga | rauemi | ||

| Te tinana / potae | WCB / stainless steel | ||

| Kōpae | WCB / stainless steel | ||

| mowhiti hiri | NBR / EPDM / PTFE / steel |

| tauira | Te pehanga ingoa (mpa) |

pehanga whakamatautau | pāmahana tika | Waenga e tika ana | |||||

| Kaha (wai) | Hiri (wai) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Tohutohu:

1.Hanga kiato, hoahoa whaitake, rigidity takirere pai, haere maeneene.

2.Ko te whakamahi i te tarapi graphite ngawari, te hiri pono, te maamaa me te mahi ngawari

Nga tono:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.Kei a matou te hangarau o te Sand or Precision casting technology,Na ka taea e matou hei hoahoa tuhi me to whakaputa.

2.Customers' waitohu e wātea ana maka ki runga ki te tinana takirere.

3. To tatou makanga katoa ki te tempering tukanga i mua i te Tukatuka.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Ko te momo valve e whakamahia ana e matou Peeke ki te kete, Ka taea hoki e matou kia rite ki nga tono a nga kaihoko.

COMPANY ADVANTAGES:

-

1.Ko matou te kaihanga mai i te 1992.

1.Ko matou te kaihanga mai i te 1992. -

2.CE,API,ISO whakaaetia.

2.CE,API,ISO whakaaetia. -

3.Te tuku tere.

3.Te tuku tere. -

4.Low utu me te kounga teitei.

4.Low utu me te kounga teitei. -

5.Te roopu mahi ngaio!

5.Te roopu mahi ngaio!