NGA TAATA HUA:

| Ingoa wahi | Rauemi | |||

| Te tinana / potae | CF8/CF3/CF8M/CF3M | |||

| Marumaru | CF8/CF3/CF8M/CF3M | |||

| Puka | Flexible graphite+304、PTFE | |||

| Hex nuts | 45 35CRMoA、25CR2MoV、 0CR18NI9 0CR17NI12MO2 |

|||

| Stud | 35CRMoA、25CR2Mo2、 0CR18NI9 0CRL17NI12MO2 |

|||

Application: It is widely used in pipelines under various working conditions, such as petrochemical, pharmaceutical, fertilizer, and power industries, to prevent the medium from flowing backward.

| Stainless Steel Lifting Check Valve Performance specifications | |||||||||

| tauira | Te pehanga ingoa (LB) |

pēhanga whakamātautau(mpa) | pāmahana tika | Waenga e tika ana | |||||

| kaha | hiri | ||||||||

| H41W-16P | 1.6 | 2.40 | 1.80 | ≤425℃ | Water, steam, petroleum, nitric acid, acetic acid, etc. | ||||

| H41W-25P | 2.5 | 3.75 | 2.75 | ||||||

| H41W-40P | 4.0 | 6.00 | 4.40 | ||||||

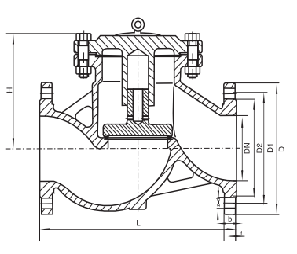

| Stainless Steel Lifting Check Valve Dimensions and connection dimensions | |||||||||

| tauira | Te diameter ingoa (mm) |

rahi(mm) | |||||||

| L | D | D1 | D2 | b | z-φd H1 |

||||

| H41W-16P | 15 | 130 | 95 | 65 | 45 | 14 | 4*φ14 | ||

| 20 | 150 | 105 | 75 | 55 | 14 | 4*φ14 | |||

| 25 | 160 | 115 | 85 | 65 | 14 | 4*φ14 | |||

| 32 | 180 | 135 | 100 | 78 | 16 | 4*φ18 | |||

| 40 | 200 | 145 | 110 | 85 | 16 | 4*φ18 | |||

| 50 | 230 | 160 | 125 | 100 | 16 | 4*φ18 | |||

| 65 | 290 | 180 | 145 | 120 | 18 | 4*φ18 | |||

| 80 | 310 | 195 | 160 | 135 | 20 | 8*φ18 | |||

| 100 | 350 | 215 | 180 | 155 | 20 | 8*φ18 | |||

| 125 | 400 | 245 | 210 | 185 | 22 | 8*φ18 | |||

| 150 | 480 | 280 | 240 | 210 | 24 | 8*φ23 | |||

| 200 | 600 | 335 | 295 | 265 | 26 | 12*φ23 | |||

| 250 | 650 | 405 | 355 | 320 | 30 | 12*φ25 | |||

| 300 | 750 | 460 | 410 | 375 | 34 | 12*φ25 | |||

| 400 | 950 | 580 | 525 | 485 | 36 | 16*φ30 | |||

PRODUCT ADVANTAGES:

1.Kei a matou te hangarau o te Sand or Precision casting technology,Na ka taea e matou hei hoahoa tuhi me to whakaputa.

2.Customers' waitohu e wātea ana maka ki runga ki te tinana takirere.

3. To tatou makanga katoa ki te tempering tukanga i mua i te Tukatuka.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7.Ko te ahua o te takirere ka whakamahia e matou nga keehi rakau ki te kete, Ka taea ano e matou

tono motuhake a te kiritaki.

COMPANY ADVANTAGES:

-

1.Ko matou te kaihanga mai i te 1992.

1.Ko matou te kaihanga mai i te 1992. -

2.CE,API,ISO whakaaetia.

2.CE,API,ISO whakaaetia. -

3.Te tuku tere.

3.Te tuku tere. -

4.Low utu me te kounga teitei.

4.Low utu me te kounga teitei. -

5.Te roopu mahi ngaio!

5.Te roopu mahi ngaio!