PRODUIT PARAMETER:

| Nominellen Duerchmiesser (mm) |

L | D 1 | D | ||||||

| PN 10/16 | PN25 / 40 | PN 10 | PN 16 | PN25 PN40 |

PN40 | ||||

| 50 | 15 | 19 | 25 | 104 | 104 | 109 | 109 | ||

| 65 | 15 | 19 | 38 | 125 | 125 | 129 | 129 | ||

| 80 | 16 | 19 | 46 | 140 | 140 | 144 | 144 | ||

| 100 | 16 | 19 | 71.5 | 160 | 160 | 170 | 170 | ||

| 125 | 17 | 19 | 95 | 185 | 185 | 196 | 196 | ||

| 150 | 19 | 29 | 114 | 220 | 220 | 226 | 226 | ||

| 200 | 26 | 29 | 140 | 270 | 270 | 286 | 293 | ||

| 250 | 29 | 38 | 188 | 330 | 331 | 343 | 355 | ||

| 300 | 38 | 51 | 216 | 380 | 386 | 403 | 420 | ||

| 350 | 38 | 45 | 263 | 440 | 446 | 460 | 477 | ||

| 400 | 48 | 55 | 305 | 491 | 495 | 517 | 549 | ||

| 450 | 48 | 60 | 356 | 541 | 558 | 567 | 574 | ||

| 500 | 58 | 70 | 406 | 596 | 620 | 622 | 626 | ||

| 600 | 68 | 78 | 482 | 698 | 732 | 734 | 745 | ||

| 700 | 70 | 80 | 562 | 813 | 804 | 831 | - | ||

| 800 | 75 | 95 | 664 | 918 | 912 | 942 | - | ||

| 900 | 75 | 95 | 738 | 1018 | 1012 | 1040 | - | ||

| 1000 | 90 | 100 | 846 | 1124 | 1126 | 1155 | - | ||

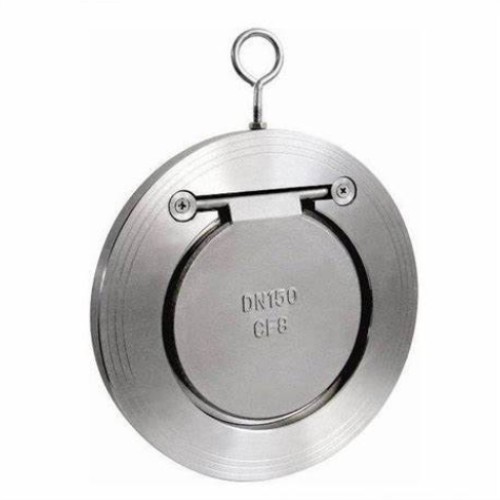

| Deel Numm | Material | ||

| Kierper / Motorkapp | WCB / stainless steel | ||

| Scheif | WCB / stainless steel | ||

| Dichtungsring | NBR / EPDM / PTFE / steel |

| Modell | Nominellen Drock (mpa) |

Testdrock | richteg Temperatur | Applicabel Medium | |||||

| Kraaft (Waasser) | Versiegelt (Waasser) | ||||||||

| H74H / X-10 | 1.0 | Working pressure * 1.5 | Working pressure * 1.1 | ≤400 ℃ | Water and seal material selection | ||||

| H74H / X-16 | 1.6 | ||||||||

| H74H / X-25 | 2.5 | ||||||||

| H74H / X-40 | 4.0 | ||||||||

Tipps:

1.Compact Struktur, raisonnabel Design, gutt Ventil Steifheit, glat Passage.

2.The Benotzung vun flexibel GRAPHITE Verpakung, zouverlässeg Dichtung, liicht a flexibel Operatioun

Uwendungen:

Industrial applications: Petroleum, Chemical, Paper Making, Fertilizer, Coal Mining,water treatment and etc.

PRODUCT ADVANTAGES:

1.We hunn Sand oder Präzisioun Goss Technologie, Also kënne mir als Är Zeechnen Design a Produktioun.

2.Customers 'Logoen sinn op de Ventilkierper gegoss.

3. All eis Goss mat Temperéierungsprozedur virun der Veraarbechtung.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding.

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7.Den Aart Ventil dee mir normalerweis benotzen Poschen ze packen, Mir kënnen och no spezifesche Client Ufuerderunge.

COMPANY ADVANTAGES:

-

1.We sinn Hiersteller Zënter 1992.

1.We sinn Hiersteller Zënter 1992. -

2.CE, API, ISO guttgeheescht.

2.CE, API, ISO guttgeheescht. -

3.Fast Liwwerung.

3.Fast Liwwerung. -

4.Low Präis mat héich Qualitéit.

4.Low Präis mat héich Qualitéit. -

5.Professionnel Aarbecht Team!

5.Professionnel Aarbecht Team!